Production

Perfect production planning for optimized processes

Scalable

Suitable for small to large production facilities

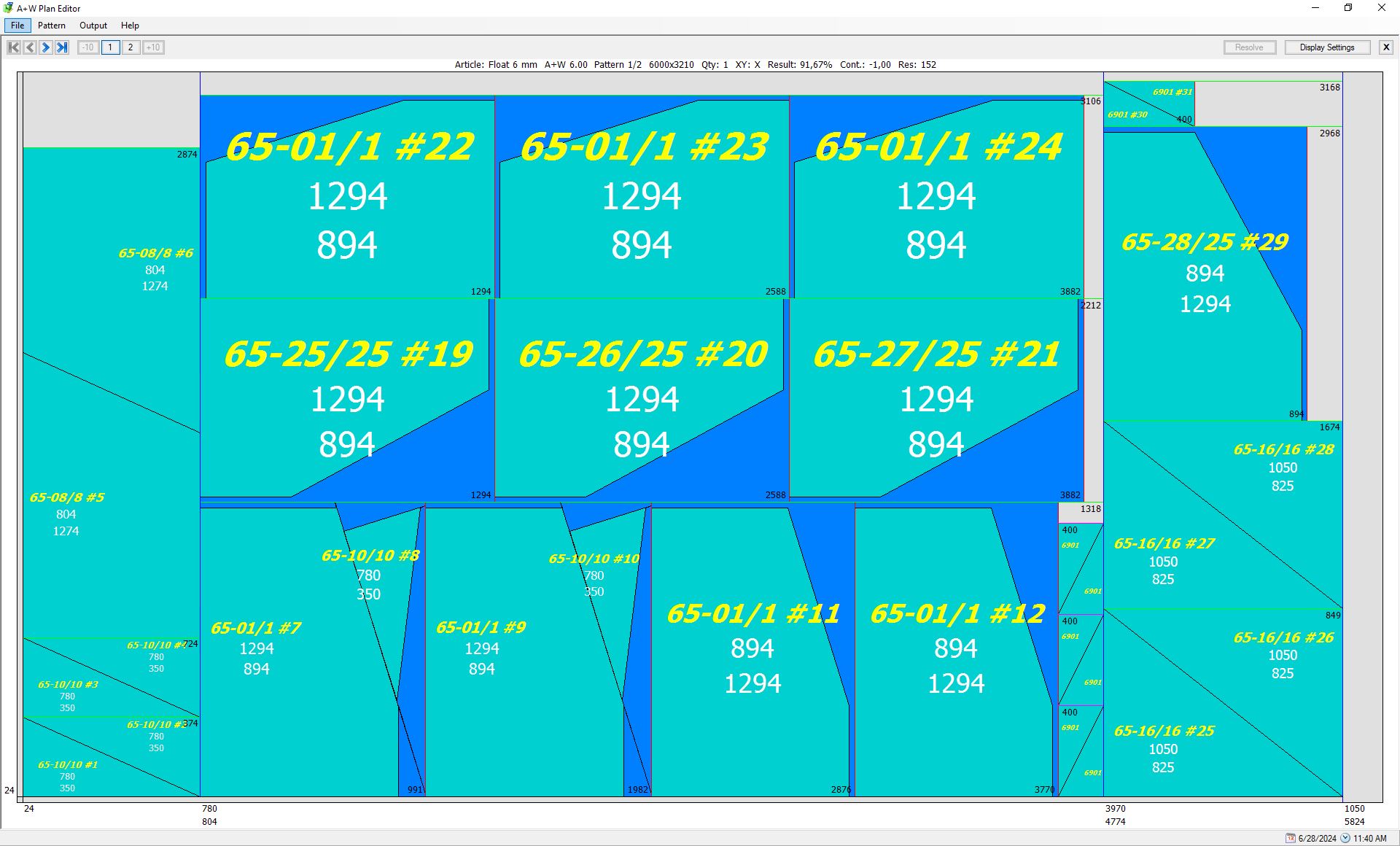

Cutting optimization

Great optimization thanks to smart algorithms

Compatible

Linkable to external ERP systems

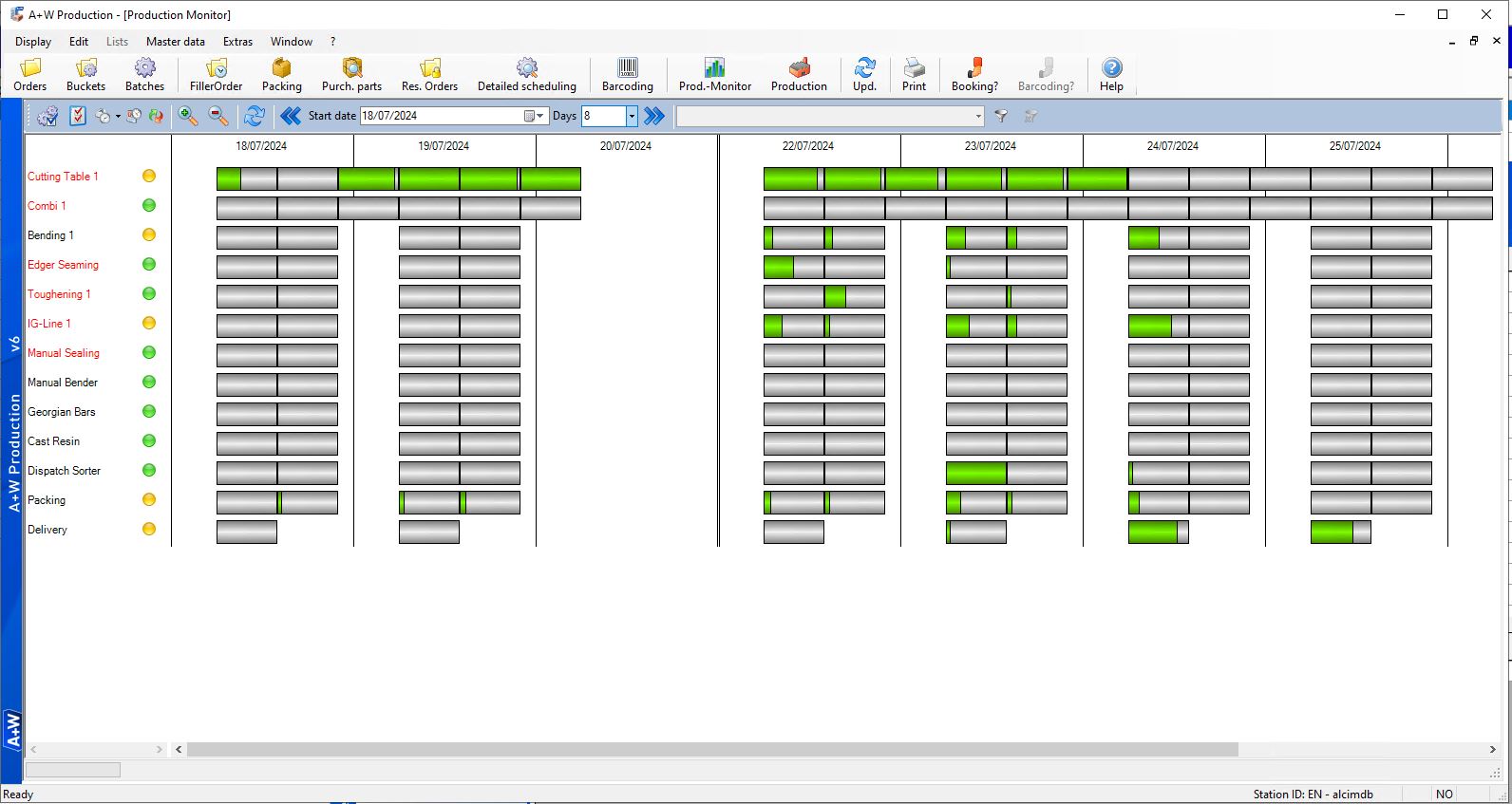

Higher-level process optimization

Combined packaging optimization

About the Product

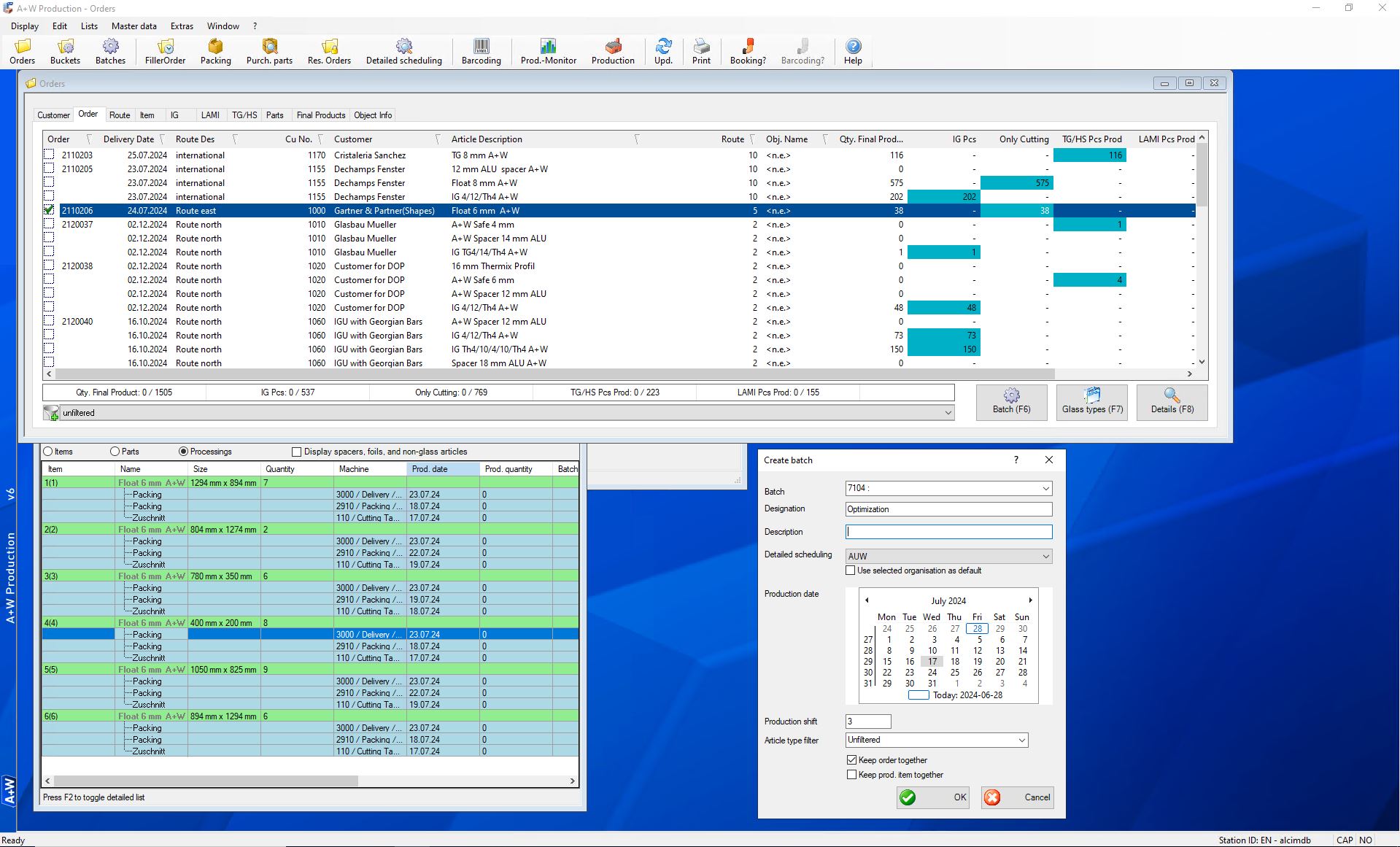

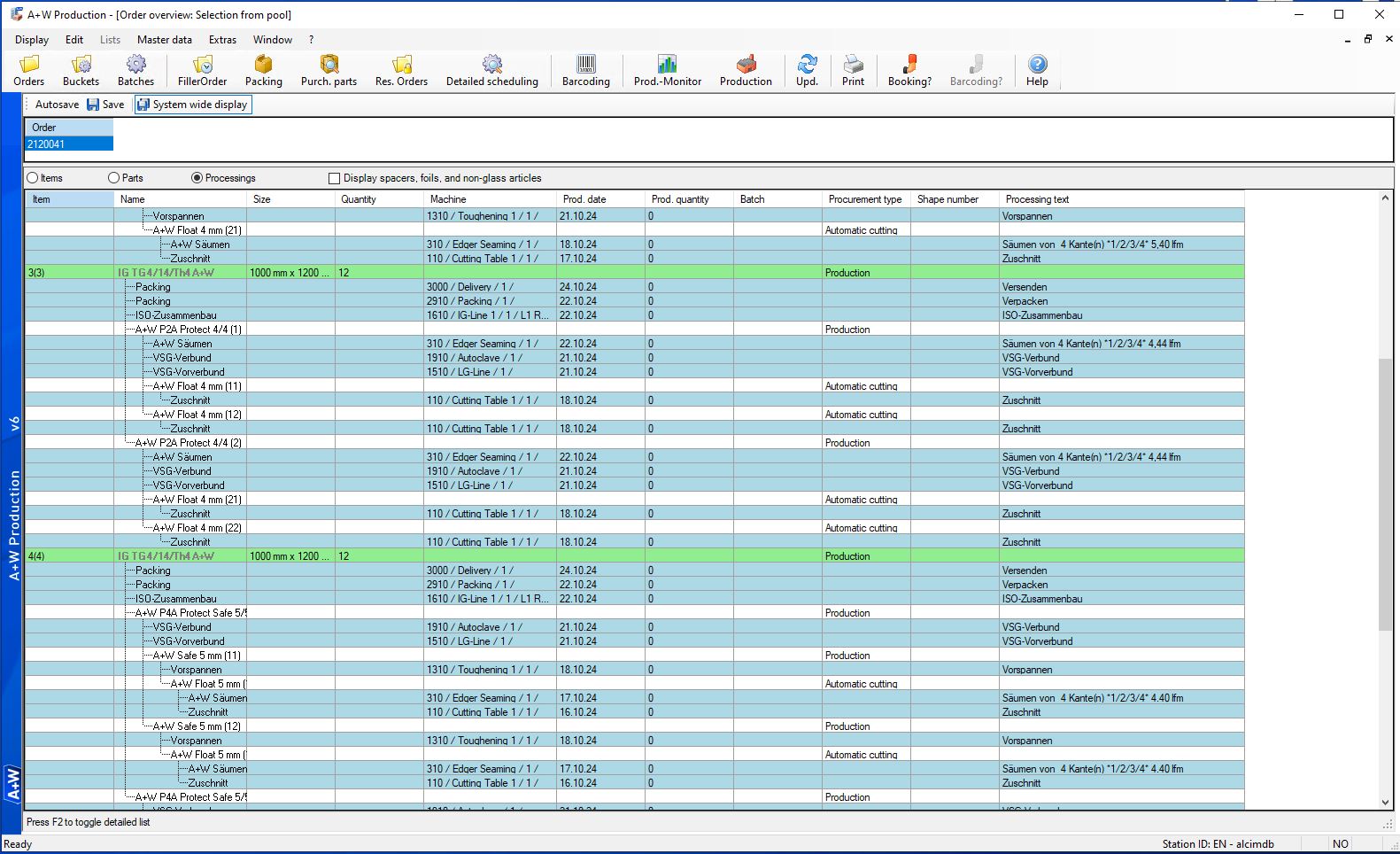

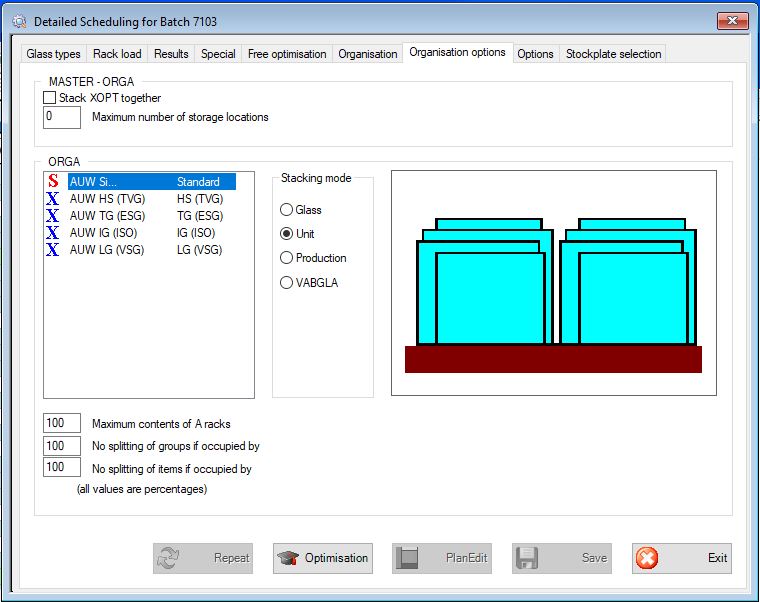

In conjunction with a more streamlined production process, you’ll find our software solution also flexibly configures production planning with various constraints, such as machines and processing sequences, all in an effort to improve your processes. Our software solution ensures optimized control over production batches, racks, and storage locations, employing state-of-the-art algorithms for precise waste optimization.

A+W Production offers flexibility and scalability, suitable for both small and large production environments. Compatible with various ERPs, it seamlessly integrates into existing systems, providing comprehensive production optimization solutions.

Unique cutting optimization algorithms guarantee maximum efficiency. Integration of capacity planning and production data acquisition enhances production control and processes.

Want to do more with A+W Production? Connect it to module extensions, such as the A+W Capacity Planner, A+W Barcode Manager, or A+W Production Terminal, which allow the system to scale and meet your newest needs and goals, so that the system grows with your company.

Functionalities and Benefits

- Plan and control production utilizing various restrictions, including machines, process sequences, etc.

- Quickly and easily manage orders and batches

- Optimize yield with state-of-the-art algorithms

- Sequence optimization as well as rack and storage space organization and optimization

- Optimization directly on racks and in boxes in shipping sequence (Software Module Extension: A+W Rack Optimizer)

- Visualization and modification of the cutting plan

- Simple machine management and direct machine control

- Efficient and graphical capacity planning (Software Module Extension: A+W Capacity Planner)

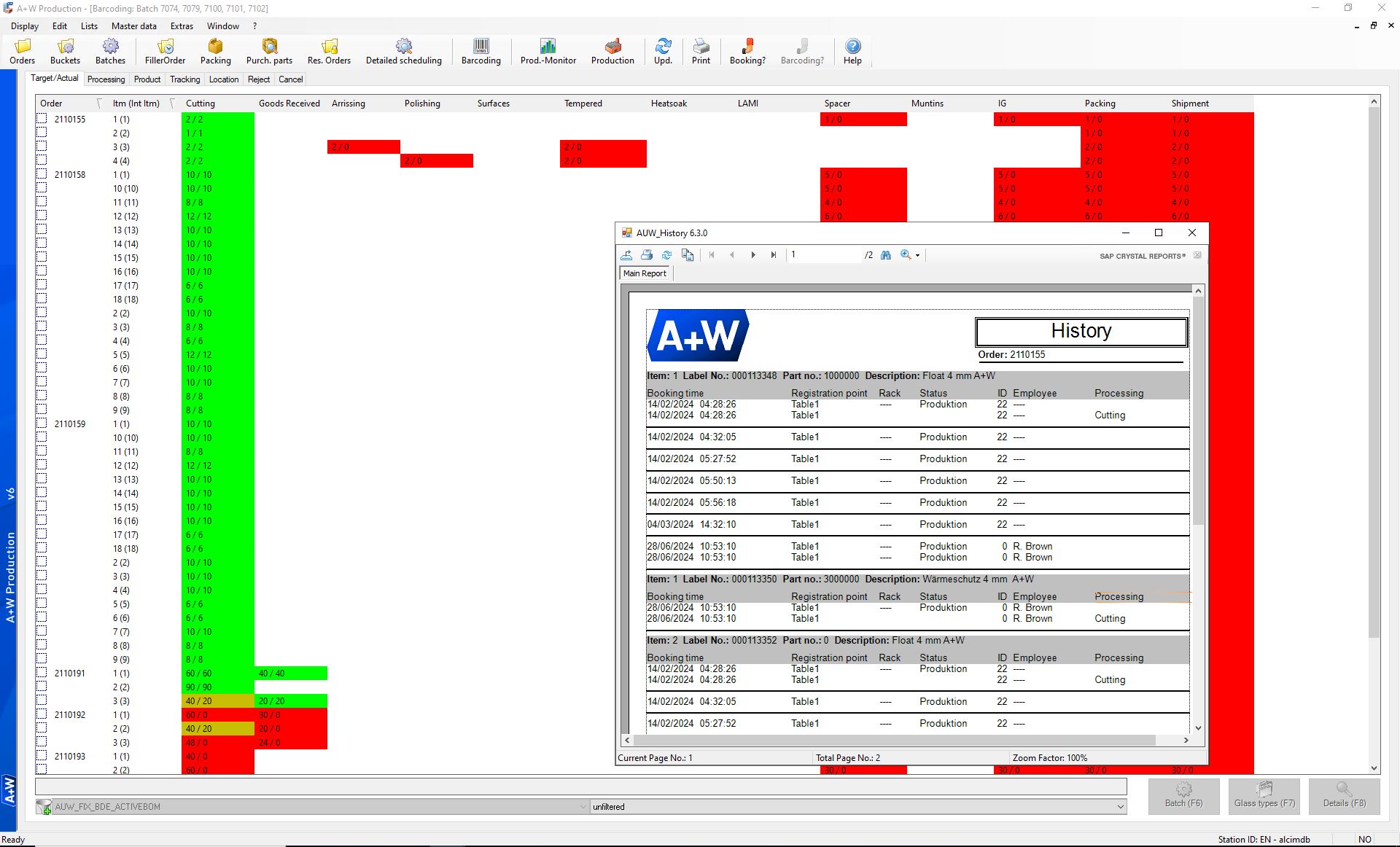

- Full integration of PDA and tracking (Software Module Extension: A+W Barcode Manager)

- Up-to-date statistics thanks to Crystal Reports and QLIK

- Printout production documents, bending texts, and barcode labels

With A+W Production, you have access to the latest production data and its current status allowing you to quickly react to changes and continuously improve. This software solution offers you a wide range of evaluation options to analyze and optimize your production processes.

Want to find out more about A+W Production? We will be happy to answer your questions and advise you on the best software solutions for your company.

Satisfied Customer Voices

A+W Clarity Reference

Spiegel Thomas

The A+W programs digitize various processes, they tap various data silos, and therefore allow our machines to communicate with one another. Only this way is it possible for us to continue increasing customer satisfaction, further increase productivity and efficiency, and thus guarantee our delivery speed of up to 48 hours for TG.

A+W Clarity Reference

Teutemacher Glas

Project implementation was usually more complicated than we would have thought, but everything always went well in the end (…) I don’t know of any better optimization solutions.

A+W Clarity Reference

Euroview

The software is the brain and backbone of the company. Our old system was not suitable for the new requirements, so we replaced it with a comprehensive solution from A+W.

Popular Add-ons

Clarity

Barcode Manager

Barcode scanning and tracking saves your employees and company time and money! A+W offers a wide array of functions to streamline production and process oversight.

Take charge of processing steps, keep track of machine utilization, and also record any breakage with ease using A+W’s barcode solution. This solution lays the groundwork for comprehensive evaluations and future planning, which are vital to your company’s current and future success. From status and storage location bookings (per user, station, machine, rack, item, and sheet) to precise processing entries and machine control via barcode scanning, our solution was designed to specifically meet your needs.

- Status and location bookings per user, station/machine, rack, item & sheet

- Machine start and control of processing via barcode reading

- Automatic reject handling (with implemented downstream concept)

- Statistical evaluations based on barcode readings (e.g. by using Crystal Reports or QLIK)

- Quality improvements based on breakage bookings

- Capacity updates based on barcode readings

- Printout of labels by A+W Production

- Flexible label design thanks to CR

- Centralized display of status information based on barcode readings by extension A+W Production Monitor and/or A+W Production Terminals

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

In addition to the quality of the software, the implementation and maintenance of such a system requires a strong, steady partner with experienced specialists who can react quickly and solve even difficult problems reliably. This is where our trust in A+W paid off completely. A+W software is a strong product, behind which there is a strong, innovative company. This is why we have satisfied customers and low complaint rates.

My father always used to strive for the optimum production solution. This also applies to the software we are using. We have therefore been using A+W software for more than 30 years, and have never looked back. Another important criterion for us is service. At A+W, this is solution-oriented; their experts know their job and communicate excellently with our staff and machinery partners.

Clarity

Smart Companion

The A+W Smart Companion revolutionizes warehouse management and logistics in the glass industry through its versatile functions and user-friendly handling. This innovative solution is usable on a mobile device under iOS and Android, offering an intuitive menu navigation that enables easy operation. The A+W Smart Companion can be deployed on various smart devices according to requirements and offers the ability to scan multiple barcodes in continuous mode.

Supporting the entire value chain, the A+W Smart Companion contributes to its digitization, saving time and costs while making processes more flexible. Warehouse management can be digitized with the A+W Smart Companion Stock Module, allowing the use of smart devices as scanner hardware for capturing inputs, outputs, transfers, and changes. During inventory, the Inventory function of the warehouse module supports the process with useful filters, checklists, and dashboards to optimize and simplify the process.

- Runs under iOS and Android

- User-friendly menu guide

- Depending on requirements, can be used on different smart devices

- Scanning of several bar codes in continuous mode

- Continuous digital stock management

- Safe and secure inventory

- Record incoming goods and stock transactions quickly and without errors

- more efficient workflows, no unnecessary running around

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Clarity

Production Terminal

A+W Production Terminal transforms production processes within the glass industry by utilizing robust capabilities and an user-friendly interface. This software solution facilitates interactive process visualization, real-time production data acquisition, and seamless control.

One notable feature the A+W Production Terminal is its ability to visualize pane setups, dimensions and processing steps, and provide employees with a clear overview of ongoing processes that require immediate intervention when necessary. Additionally, each terminal supports the display of CAD drawings and document links, which enhance communication and collaboration throughout production.

The integration of A+W Barcode Manager with the A+W Production Terminal is another key aspect, enabling efficient booking of breakage slices and reasons, along with machine status feedback and automatic scrap handling, which collectively enhances productivity, efficiency and processing quality.

- Visualize pane structures, dimensions, and processing steps

- Display of CAD drawings

- Document links for enhanced communication and collaboration

- Booking of breakage and reason

- Booking and feedback of machine status

- Automatic reject handling with implemented downstream concept

- Fully customizable user interface

- Control via foot panel for convenient operation

- Display rack information for subsequent processes

- Online printing of labels

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

The staff is not supposed to run around the shop floor to gather information but they shall have all the information they need for the production step on hand right at their workstation.

Thanks to A+W Production and A+W Barcoding, the shop floor as well as the A+W Business order processing system know the processing status of every sheet, any time. The staff can answer customers’ enquiries right away on the phone – our customers appreciate this!

Clarity

Realtime Optimizer

The A+W Realtime Optimizer revolutionizes cutting optimization in glass production by enabling flexible and extensive interventions in manufacturing processes. Even after optimization, runs can be linked, split, and reassembled.

Furthermore, optimization parameters (such as edge cut, etc.) can be changed immediately before cutting. The system distributes optimization runs online to different cutting tables, seamlessly integrates rush orders and damaged glass, while ensuring compliance with the original stacking sequences.

The intelligent utilization of leftover plates maximizes glass yield by automatically or manually identifying and linking residual plates. Additionally, the A+W Realtime Optimizer offers efficient breakage management, marking damaged panes and enabling automatic reproduction.

- Online re-optimization of created jobs from A+W Production or A+W Business Pro (same glass type)

- Consideration of production sequence from the production system

- Possibility of entering rush lites / rush jobs

- Quick-Optimization after cutting was started

- Reduction of residue plates by using rush jobs, breakage, or sheets from following optimizations / jobs

- Dynamic re-optimization of breakage

- Online control of cutting tables and breakout display

- Avoids residue plates by linking and mixing of cutting jobs

- Improves the yield and cutting performance

- Managing local and global breakage with re-optimization

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Standalone

Solutions without ERP system

A+W is a reliable partner that continues to enhance its products and offer new solutions. A+W has many interface solutions with other providers and it works exceedingly well with all machine partners.

With A+W Production, we can plan and conduct our production much more efficiently, especially in the interplay with production control and completion reporting by plant data collection. Currently, we are working with A+W on the implementation of a breakage pool, with which we can reproduce defective lites quickly.