THE HISTORY OF A+W

Success is no coincidence

Our Story of Success

Since 1977, we develop innovative solutions for the glass industry. A+W has evolved over the last 40 years to be the most established provider of ERP and PPS software for the glass and fenestration industry.

You can become and remain market leader only through consistent innovation and proximity to your customers around the world. Together with our customers and partners we shape the future.

A+W is a company with a long tradition – See for yourself!

2014 MOVING TO POHLHEIM

After nearly a quarter century of intensive use, the company headquarters in Linden are in urgent need of renovation. Conversions are required partially due to building law, but also ‘upgrades’, for example in the field of heat protection in summer.

This would have required huge investment. The management therefore decides for the third move in the company’s history.

The new company headquarters in Pohlheim are just a few kilometers away from Linden. Visitors will find modern and appealing office buildings with excellent conditions for meetings, trainings, etc..

After extensive renovation, a friendly, light-flooded office center in the middle of the charming park-like landscape has been created that integrates workstations for intensive mental work with comfortable communication zones. The new buildings offer space for more than 150 employees.

2013 ACQUISITION BY CONSTELLATION

At 5 February 2013, the final contracts for the acquisition of A+W by Constellation’s Friedman Operating Group were signed.

A+W will operate as an independent division of Friedman, and will continue to develop, enhance, and market their glass and fenestration industry software solutions world-wide.

With this acquisition, Friedman Corporation will extend its product range of ERP and PPS solutions for producers and retailers considerably and strengthen its presence in the glass-, window-, and construction element industries.

In this context, the ALBAT+WIRSAM Software GmbH has been renamed in A+W Software GmbH.

2012 A+W DRAGONFLY

‘DRAGONFLY‘ is the name of a fascinating project which has heralded in the start of a completely new product generation at A+W.

The first pilot installations have turned ‘DRAGONFLY‘ into the product ‘A+W Business’, the new ERP solution for medium-sized flat glass processors and IG producers.

2010 EVERY THIRD WINDOW

CANTOR has become the established product on the German-speaking market in the last two decades.

2007 PART OF THE GLASTON CORPORATION

In July 2007, ALBAT+WIRSAM Software AG becomes a part of the Finnish Glaston Group.

Glaston integrates A+W as their business area “Software Solutions”, thus ensuring a high degree of independence for A+W.

2005 FIRST DYNAMIC OPTIMIZATION

Wolff+Meier and A+W continue their close cooperation in the new millennium.

The pilot project for controlling the dynamic glass cutting optimization by A+W’s software system DynOpt and the Hegla SortJet proves an unqualified success.

Visitors from all over the world go on a pilgrimage to Langgöns (Hessen) to see the solution for themselves. With this dynamic optimization system, Wolff+Meier achieve a constant flow of glass which results in optimum yield.

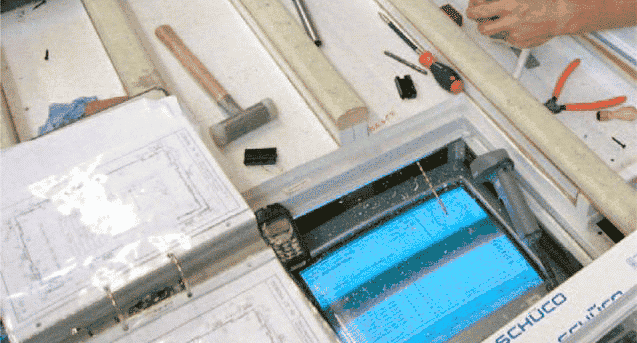

2003 PAPERLESS WINDOW CONSTRUCTION

Schüco is the first CANTOR customer whose window production is equipped with monitors.

With the production control system CANTOR CIM, the workers are provided with digital production papers right at their terminal, showing all information on the element on hand. This guarantees that the data are always up to date. Carrying stacks of papers around the shop floor is a thing of the past since the installation of 160 digital terminals at Schüco.

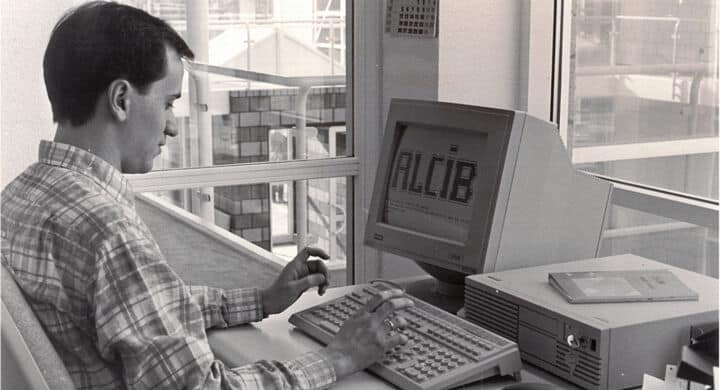

1997 PRODUCTION PROCESS NETWORK

For the first time, all processes from order entry, order processing, and production control up to dispatch are networked.

In 1997, A+W develops a program which makes disks, labels, and paperwork on the shop floor dispensable: ALCIM.

Production was revolutionized by ALCIM in 1997 because information was available right where it was required. Order processing data are available online at the cutting lines, benders, sealing robots, and applicators. Monitors on the shop floor are a complete novelty.

A+W still revolutionize production with similar systems. Needless to say that the cooperation with machinery manufacturers is as close as ever.

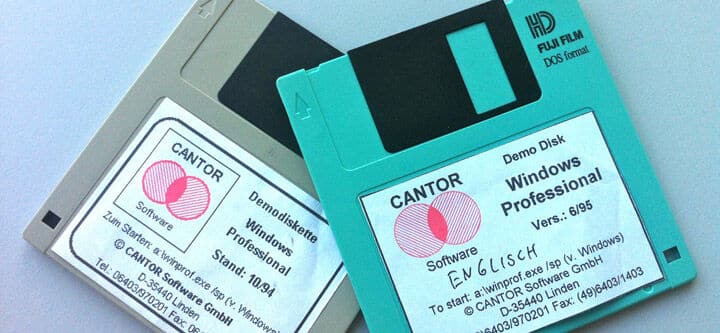

1994 LAUNCHING OF CANTOR

1994 sees the implementation of the first MS Windows-based window construction software package with a graphic user interface made by A+W.

6 months after having been launched on the market, contracts are signed for the installation of the CANTOR system in twelve big window factories and at 800 dealers.

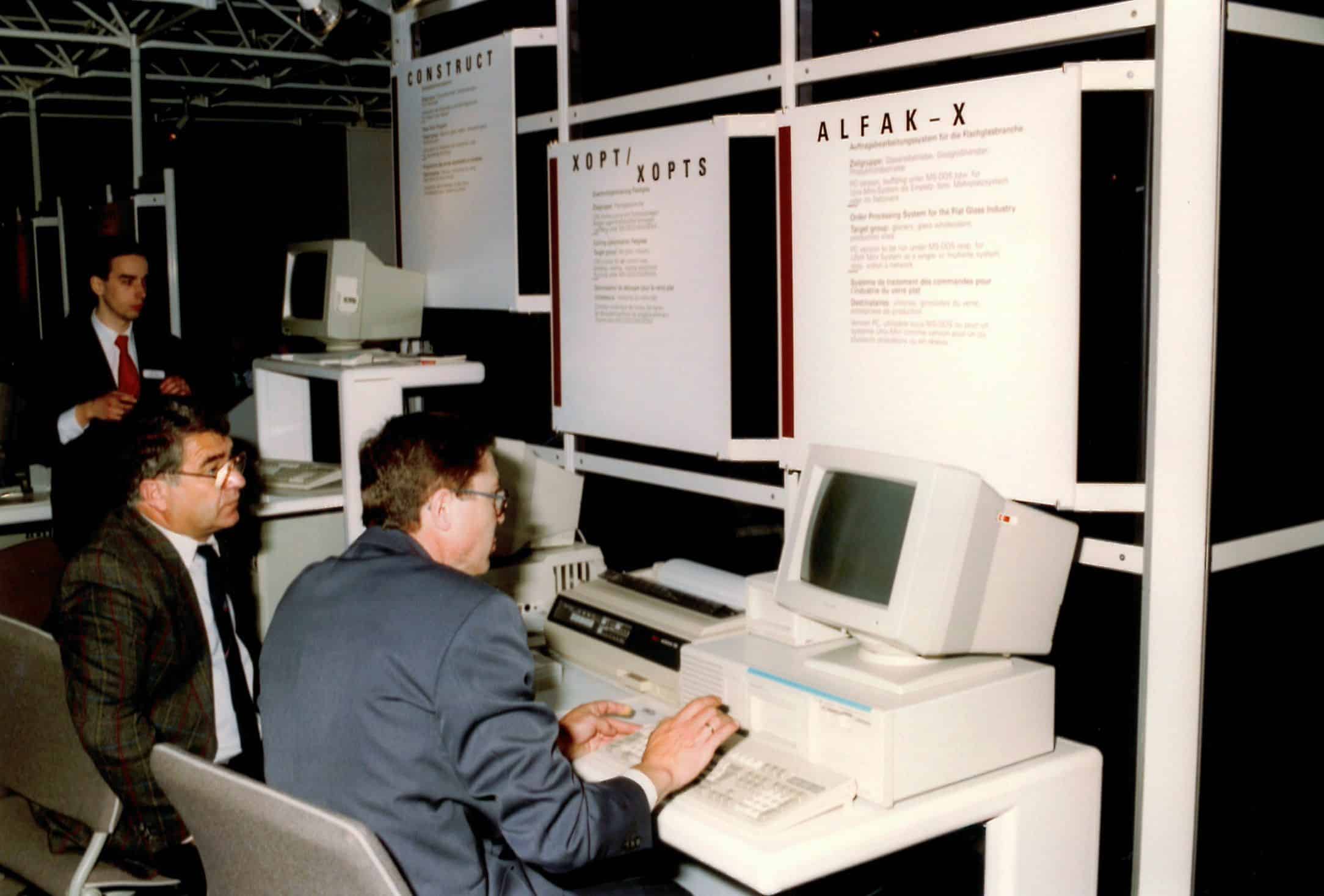

1994 GLASSTEC IN DUSSELDORF

The nineties saw A+W as a fixed element of this main event for the flat glass industry.

Exhibition booths used to be rather bigger in those days because the monitors alone required so much more space…

1991 FIRST ERP SYSTEM

A+W started the development of the first comprehensive ERP solution (ALCIB) for the glass industry at the end of the eighties.

In the early nineties, this system conquered the world market; thanks to their innovative products, A+W quickly became market leader in this field.

1990 MOVE TO NEW HEADQUARTERS

After constant expansion during the eighties, the office bursts its seams. The owners of A+W therefore decided to build new headquarters.

This has been planned with foresight so that it offers ample space for the 200 employees of A+W in Linden.

1980 FIRST PPS SYSTEM

In 1980, the first production planning software for the flat glass industry is launched on the market.

A+W have launched the first ever order processing system for the glass industry, ALFAK. In 1980 there were already more than 100 successful installations of the glass cutting optimization TRAOPT and the order processing system ALFAK.

The world-wide success of this system makes ALBAT+WIRSAM expand even further. Their business premises are moved from the office in the cellar of Wirsam’s family home to a spacious villa.

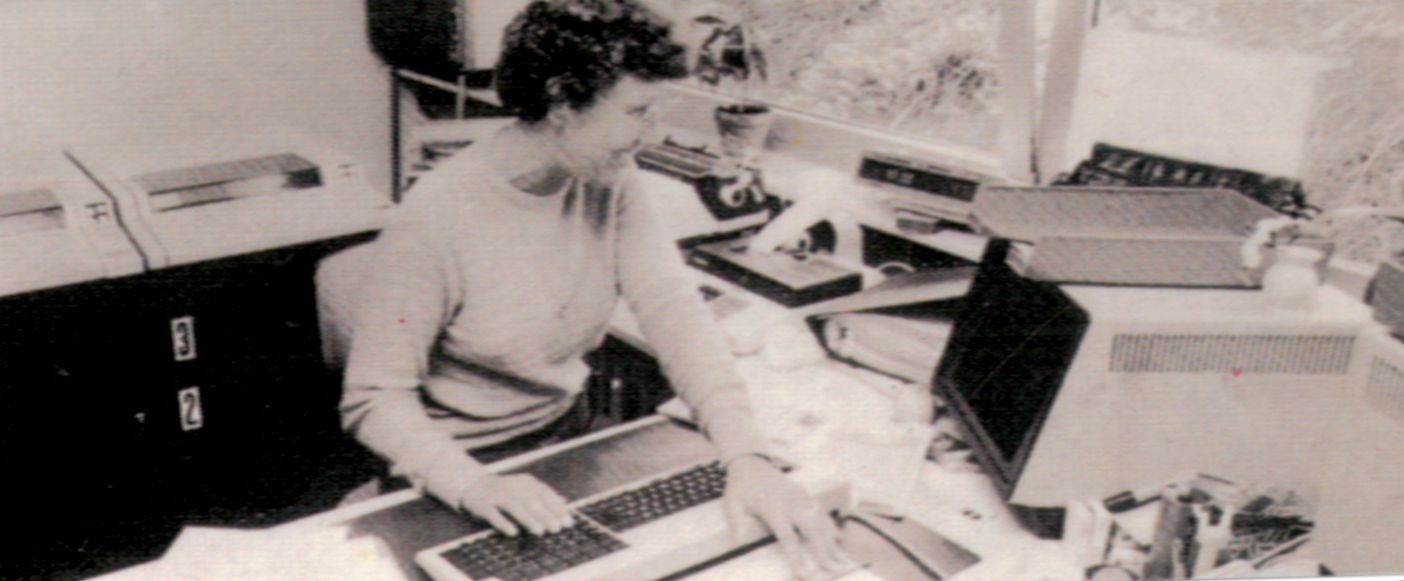

1978 FIRST GLASS CUTTING OPTIMIZATION

EDV in the seventies with enormous 126Kb RAM and 20Mb hard drive.

This is the computer (NIXDORF 8870) used by Dr. Renate Albat and Dr. Bernd Wirsam for developing their first optimization programs and the first order processing software ALFAK for glass processors Wolff+Meier of Langgöns (Hessen).

1977 ESTABLISHED

The physics lecturer Dr. Renate Albat and Dr. Bernd Wirsam from Giessen University pursued with their cutting optimization for flat glass the vision to reduce the waste by at least 10%.

One evening, Henning Meier, glass processor of Langgöns /Germany, discussed the problem of cutting optimization in the flat glass industry with his friend and neighbor, Dr. Bernd Wirsam.

Dr. Bernd Wirsam – lecturer in the department of physics at Gießen University – checked possible algorithms and solutions for his friend – without encountering much know-how on this sector however, let alone a solution. Together with his colleague Dr. Renate Albat he decides to develop a solution for the flat glass industry.

In April 1977, the two physicists establish ALBAT+WIRSAM Software GbR. Their vision: Reducing the waste by at least 10% by means of their cutting optimization for flat glass.