Production

Perfect production planning for optimized processes

Scalable

Suitable for small to large production facilities

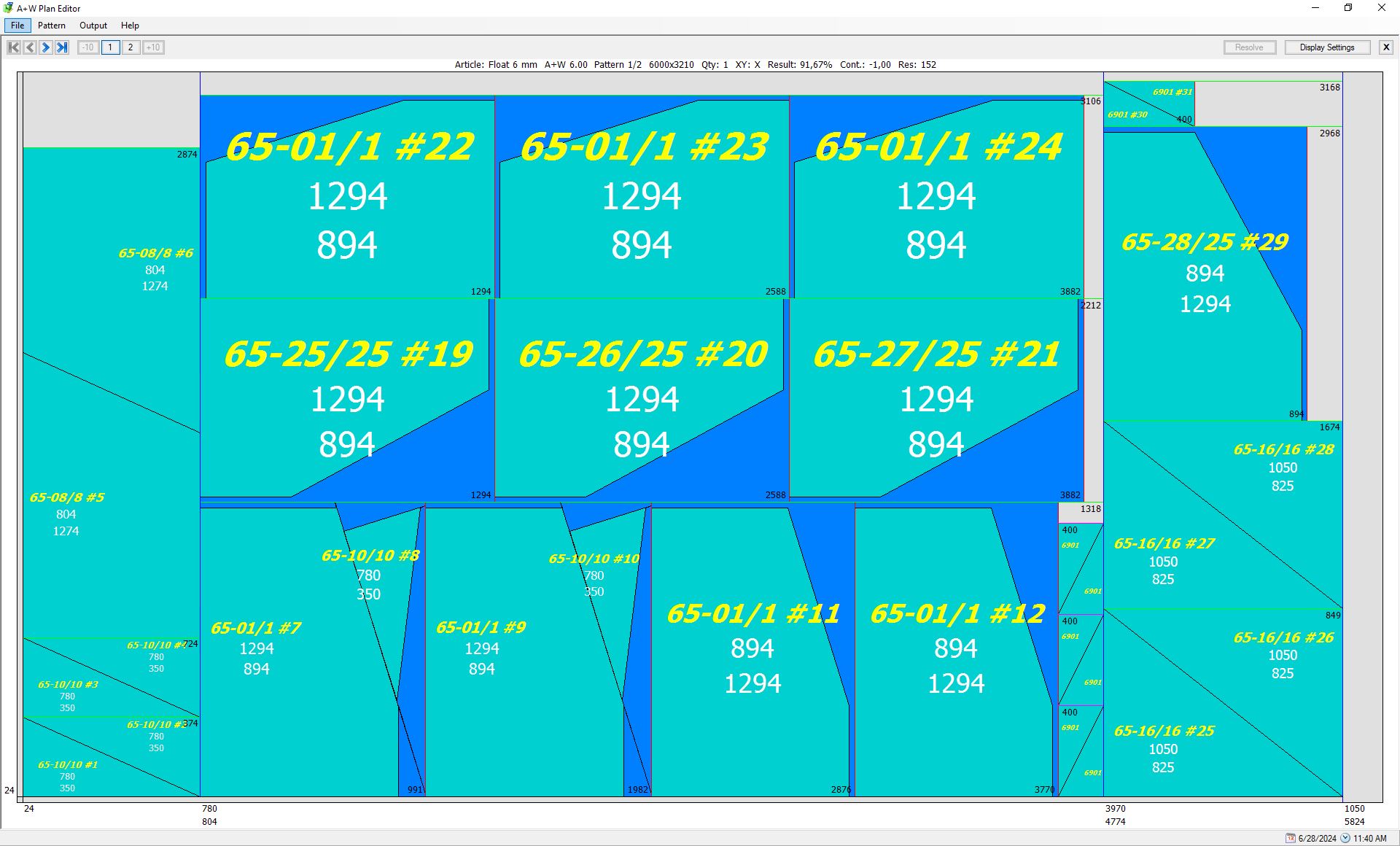

Cutting optimization

Great optimization thanks to smart algorithms

Compatible

Linkable to external ERP systems

Higher-level process optimization

Combined packaging optimization

About the Product

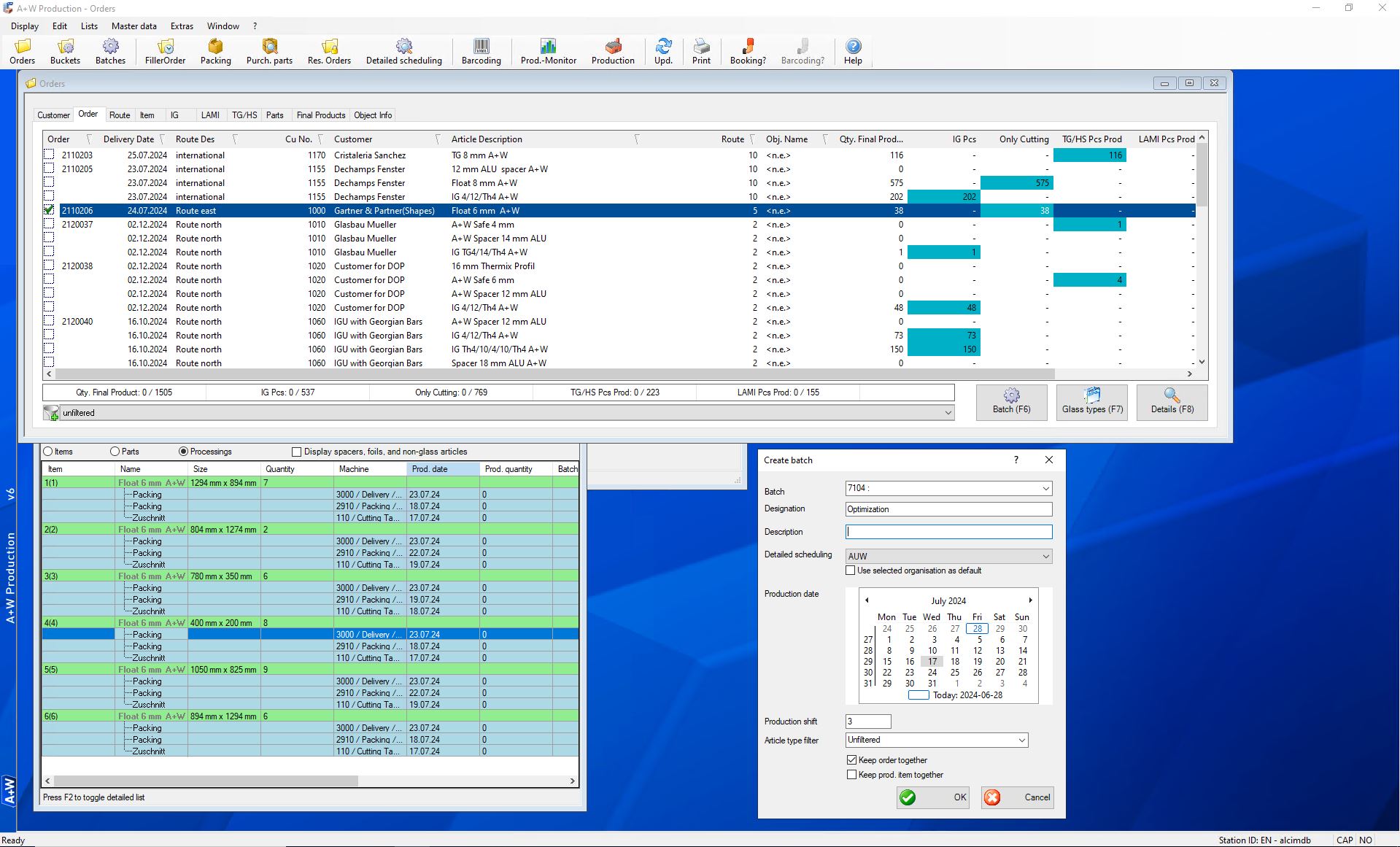

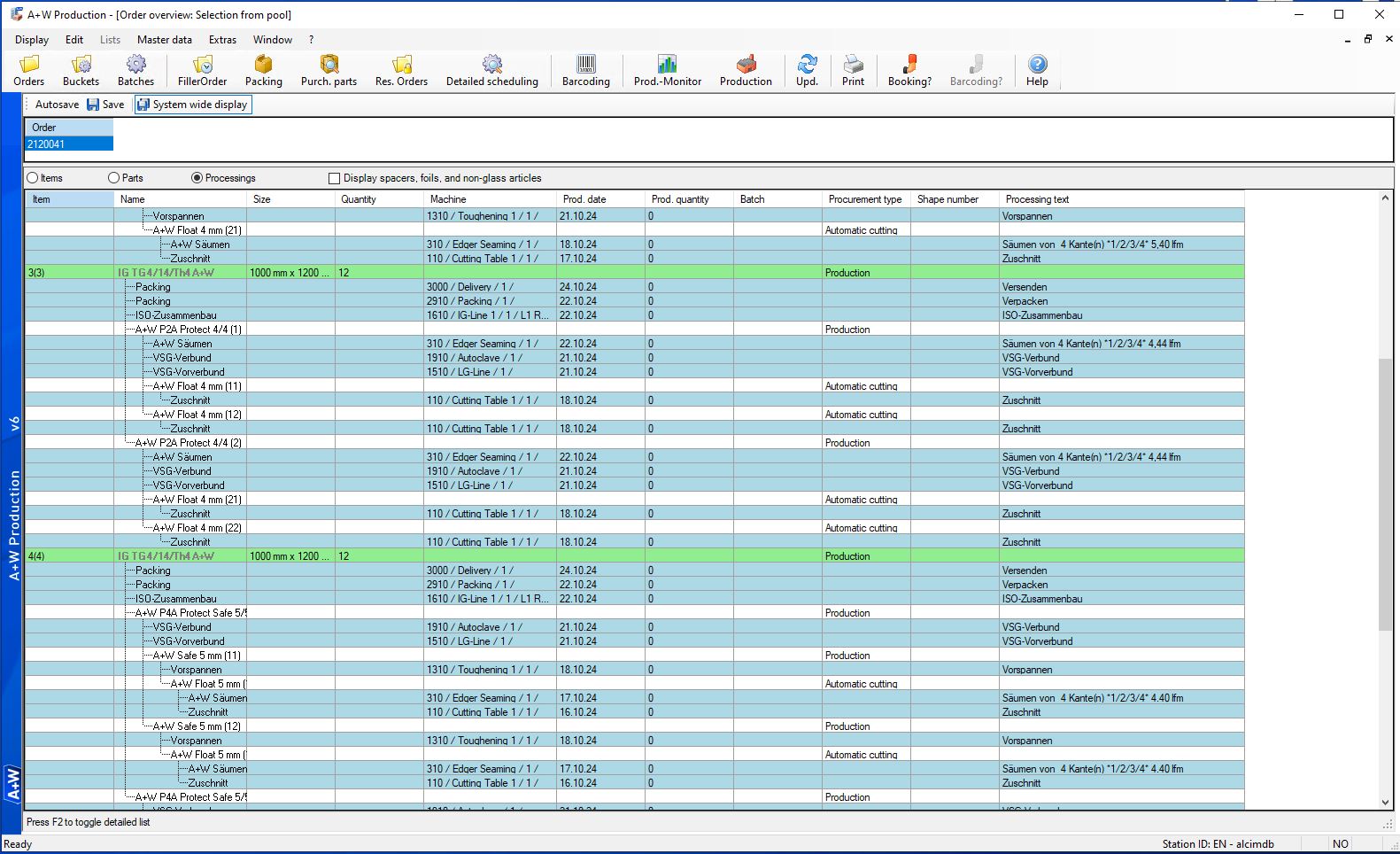

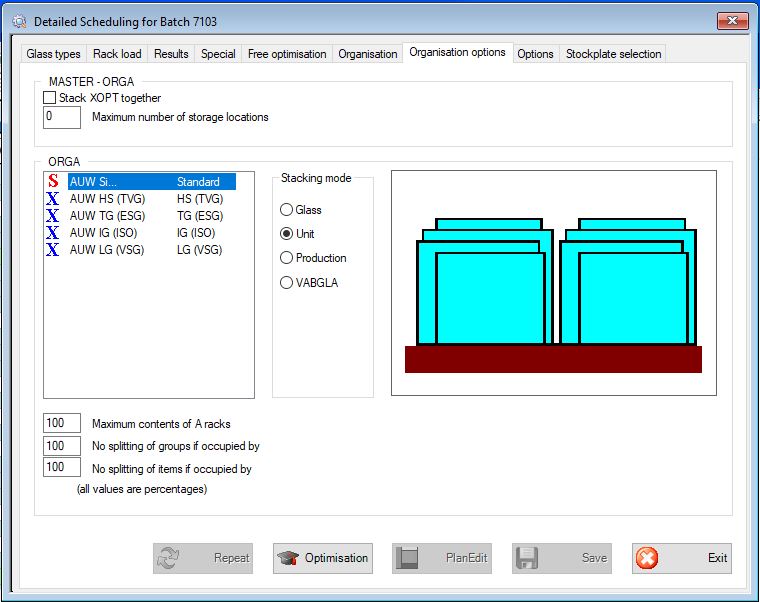

In conjunction with a more streamlined production process, you’ll find our software solution also flexibly configures production planning with various constraints, such as machines and processing sequences, all in an effort to improve your processes. Our software solution ensures optimized control over production batches, racks, and storage locations, employing state-of-the-art algorithms for precise waste optimization.

A+W Production offers flexibility and scalability, suitable for both small and large production environments. Compatible with various ERPs, it seamlessly integrates into existing systems, providing comprehensive production optimization solutions.

Unique cutting optimization algorithms guarantee maximum efficiency. Integration of capacity planning and production data acquisition enhances production control and processes.

Want to do more with A+W Production? Connect it to module extensions, such as the A+W Capacity Planner, A+W Barcode Manager, or A+W Production Terminal, which allow the system to scale and meet your newest needs and goals, so that the system grows with your company.

Functionalities and Benefits

- Plan and control production utilizing various restrictions, including machines, process sequences, etc.

- Quickly and easily manage orders and batches

- Optimize yield with state-of-the-art algorithms

- Sequence optimization as well as rack and storage space organization and optimization

- Optimization directly on racks and in boxes in shipping sequence (Software Module Extension: A+W Rack Optimizer)

- Visualization and modification of the cutting plan

- Simple machine management and direct machine control

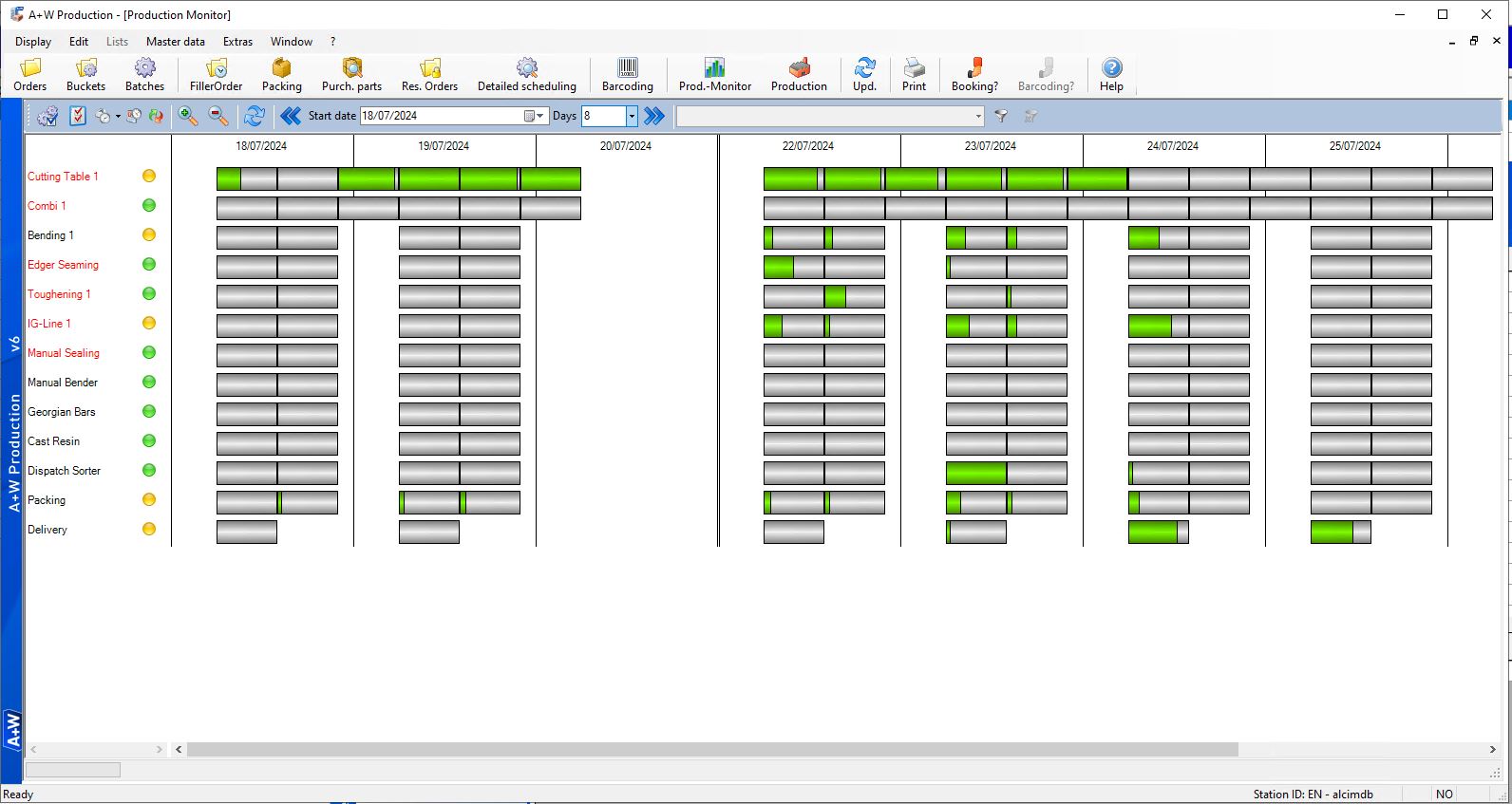

- Efficient and graphical capacity planning (Software Module Extension: A+W Capacity Planner)

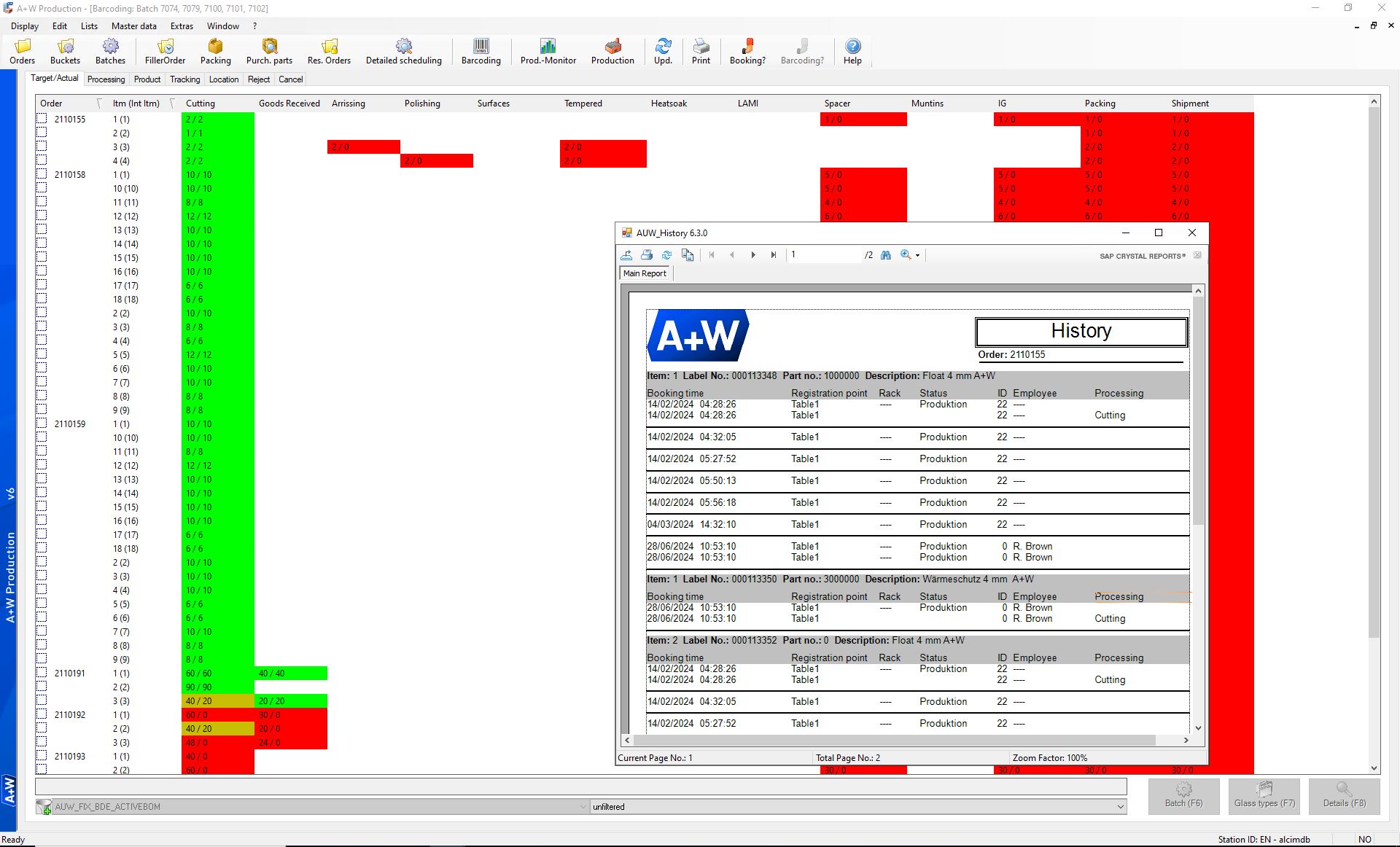

- Full integration of PDA and tracking (Software Module Extension: A+W Barcode Manager)

- Up-to-date statistics thanks to Crystal Reports and QLIK

- Printout production documents, bending texts, and barcode labels

With A+W Production, you have access to the latest production data and its current status allowing you to quickly react to changes and continuously improve. This software solution offers you a wide range of evaluation options to analyze and optimize your production processes.

Want to find out more about A+W Production? We will be happy to answer your questions and advise you on the best software solutions for your company.

Satisfied Customer Voices

A+W Clarity Reference

BarteltGLASBerlin

The future is not something you have, it’s something you make!

A+W Clarity Reference

Glas Herzog

A+W Business 6 is the best version of the commercial A+W software. The system works reliably, and thanks to the BOM concept, all products can be mapped. And if something gets hung up, A+W offers reliable service – our contact people, with whom we have been working for years, are experts, they help us quickly and easily.

A+W Clarity Reference

Reflex

My father always used to strive for the optimum production solution. This also applies to the software we are using. We have therefore been using A+W software for more than 30 years, and have never looked back. Another important criterion for us is service. At A+W, this is solution-oriented; their experts know their job and communicate excellently with our staff and machinery partners.

Popular Add-ons

Clarity

Rack Optimizer

A+W Rack Optimizer transforms the packaging process in insulating glass production by enabling direct packaging and maximing the utilization of packaging materials. This ensures consistent packaging quality, while reducing reliance on employee expertise.

The software considers unloading sequences and allows for customized sequencing to balance weight and optimize rack loading/unloading, minimizing the needs for order picking and reducing transport costs A 3D visualization provides detailed previews and graphic instructions for packaging optimization.

- Increasing productivity on the IG line, addressing bottlenecks

- Eliminate re-sorting requirements in dispatch

- Potential use of robots for stacking and packaging

- Reduced breakage and rejects through automated glass packaging

- Automatic weight balancing and limit check for packing racks

- 3D pack view for detailed rack loading visualization and item identification

- Manual lite movement using the 3D pack view editor

- Special mode for cases

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Standalone

Solutions without ERP system

Clarity

Dashboard

With A+W Dashboard, you gain a clear overview of key production metrics, allowing swift responses to machine and work bottlenecks. Its graphical presentation of production data facilitates intuitive monitoring, while also allowing desktop PCs, tablets, or smartphones access to information anytime, anywhere.

Our modern and simple HTML configurator enables personalized views, adaptable to various devices, ensuring convenient access to data from the past 24 hours to real-time updates. Fully integrated with A+W Production, A+W’s Dashboard provides key performance indicators derived from PDA postings, which is then augmented by statistical insights from BI tools for comprehensive control.

Unique features of A+W Dashboard include machine performance overview, which displays booking data per machine, and mobile accessibility, allowing you to set target values for performance assessment. The visualization of data makes setting target values for success easier.

- Graphical representation of KPIs

- Real-time detection of bottlenecks for production control and high information density for comprehensive insights

- Modern and simple HTML configurator for personalized views

- Compatible across desktop and mobile devices

- Seamless integration with A+W Production for enhanced performance tracking, including KPIs based on barcoding bookings

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Clarity

Realtime Optimizer

The A+W Realtime Optimizer revolutionizes cutting optimization in glass production by enabling flexible and extensive interventions in manufacturing processes. Even after optimization, runs can be linked, split, and reassembled.

Furthermore, optimization parameters (such as edge cut, etc.) can be changed immediately before cutting. The system distributes optimization runs online to different cutting tables, seamlessly integrates rush orders and damaged glass, while ensuring compliance with the original stacking sequences.

The intelligent utilization of leftover plates maximizes glass yield by automatically or manually identifying and linking residual plates. Additionally, the A+W Realtime Optimizer offers efficient breakage management, marking damaged panes and enabling automatic reproduction.

- Online re-optimization of created jobs from A+W Production or A+W Business Pro (same glass type)

- Consideration of production sequence from the production system

- Possibility of entering rush lites / rush jobs

- Quick-Optimization after cutting was started

- Reduction of residue plates by using rush jobs, breakage, or sheets from following optimizations / jobs

- Dynamic re-optimization of breakage

- Online control of cutting tables and breakout display

- Avoids residue plates by linking and mixing of cutting jobs

- Improves the yield and cutting performance

- Managing local and global breakage with re-optimization

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Standalone

Solutions without ERP system

With A+W Production, we can plan and conduct our production much more efficiently, especially in the interplay with production control and completion reporting by plant data collection. Currently, we are working with A+W on the implementation of a breakage pool, with which we can reproduce defective lites quickly.

In addition to the quality of the software, the implementation and maintenance of such a system requires a strong, steady partner with experienced specialists who can react quickly and solve even difficult problems reliably. This is where our trust in A+W paid off completely. A+W software is a strong product, behind which there is a strong, innovative company. This is why we have satisfied customers and low complaint rates.

Clarity

Capacity Planner

A+W Capacity Planner provides a comprehensive overview of your production facilities’ available capacities and their utilization, which empowers you to effectively plan your production. This software solution also allows you to easily manage shifts, capacities, bottlenecks, and workloads for efficient processes.

This software offers flexibility in defining machine and operation restrictions, while also automatically adjusting production dates if capacities are insufficient. You can also calculate delivery dates, processing timelines, and costs effortlessly, while distributing loads across machines.

With A+W Capacity Planner, you can optimize production progress and costs by considering fixed processing times and campaign planning. By taking this information into account, you can reserve capacities and prioritize customer groups for streamlined order processing. Additionally, you can maintain control with detailed production progress displays and integration with A+W Barcode Manager and/or A+W Production Terminals. By being able to scale and combine A+W modules, you have more control and understand of every process in your facility.

- Display machine capacities and utilization information

- Easy management of shifts, capacities, bottlenecks and workload

- Free, formula-based machine and work process restrictions

- Automatically transfer production dates when capacity is insufficient at dispatch

- Calculate delivery dates and processing timelines

- Automatic calculation processing dates, durations and costs during import

- Automatic load distribution on machines based on work processes

- Cost calculation for orders and quotes

- Management of reservations and campaigns

- Directly communicate information to the ERP system

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Thanks to A+W Production and A+W Barcoding, the shop floor as well as the A+W Business order processing system know the processing status of every sheet, any time. The staff can answer customers’ enquiries right away on the phone – our customers appreciate this!

With A+W iQuote, anything that is ordered can actually be built. The entire order runs through a restriction check based on master data stored in A+W Business. The customer transmits a technically correct complete order to us. There are no questions and time-consuming clarifications by telephone or e-mail. This is how we can achieve much greater efficiency in the entire order process.