Production

Perfect production planning for optimized processes

Scalable

Suitable for small to large production facilities

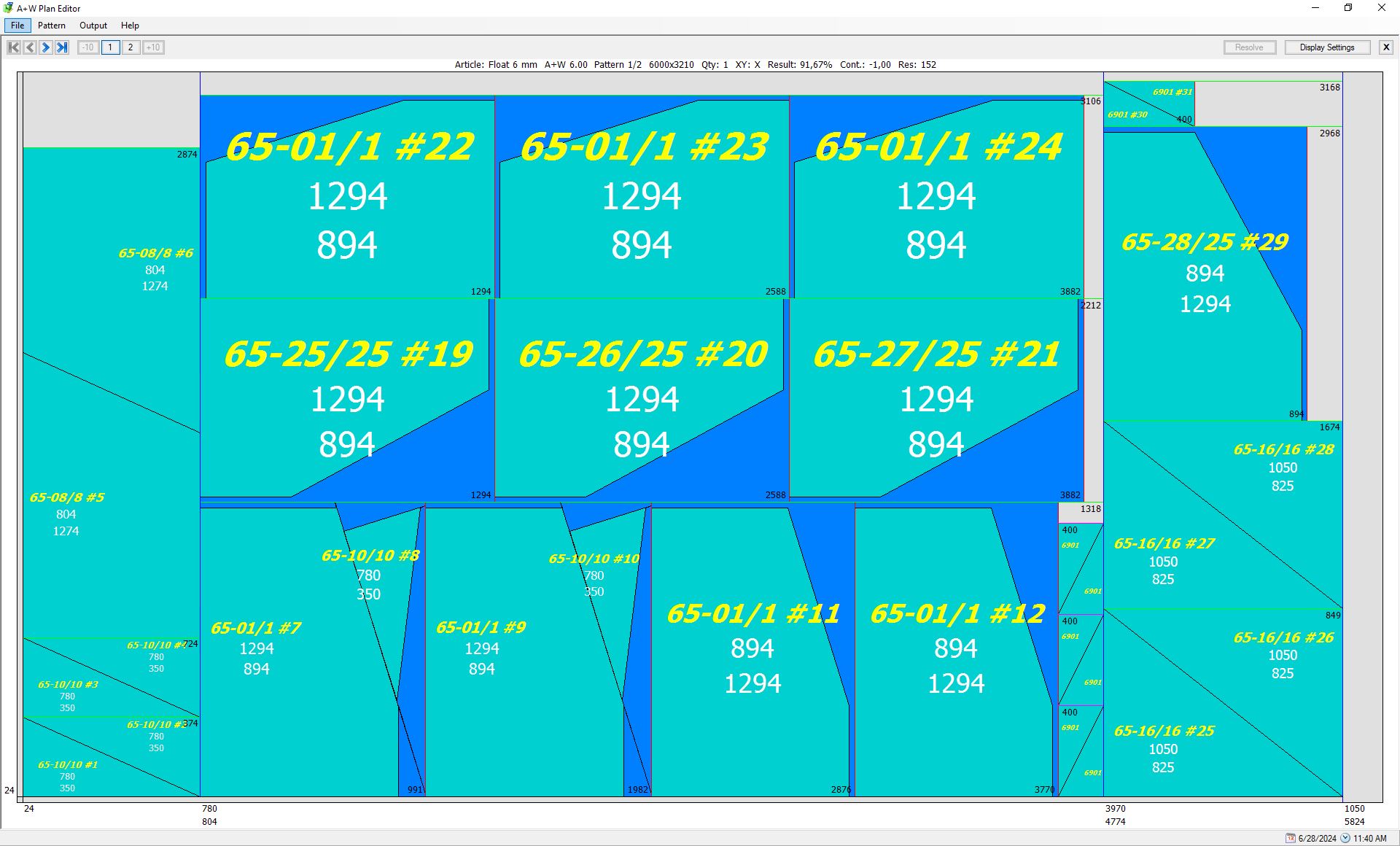

Cutting optimization

Great optimization thanks to smart algorithms

Compatible

Linkable to external ERP systems

Higher-level process optimization

Combined packaging optimization

About the Product

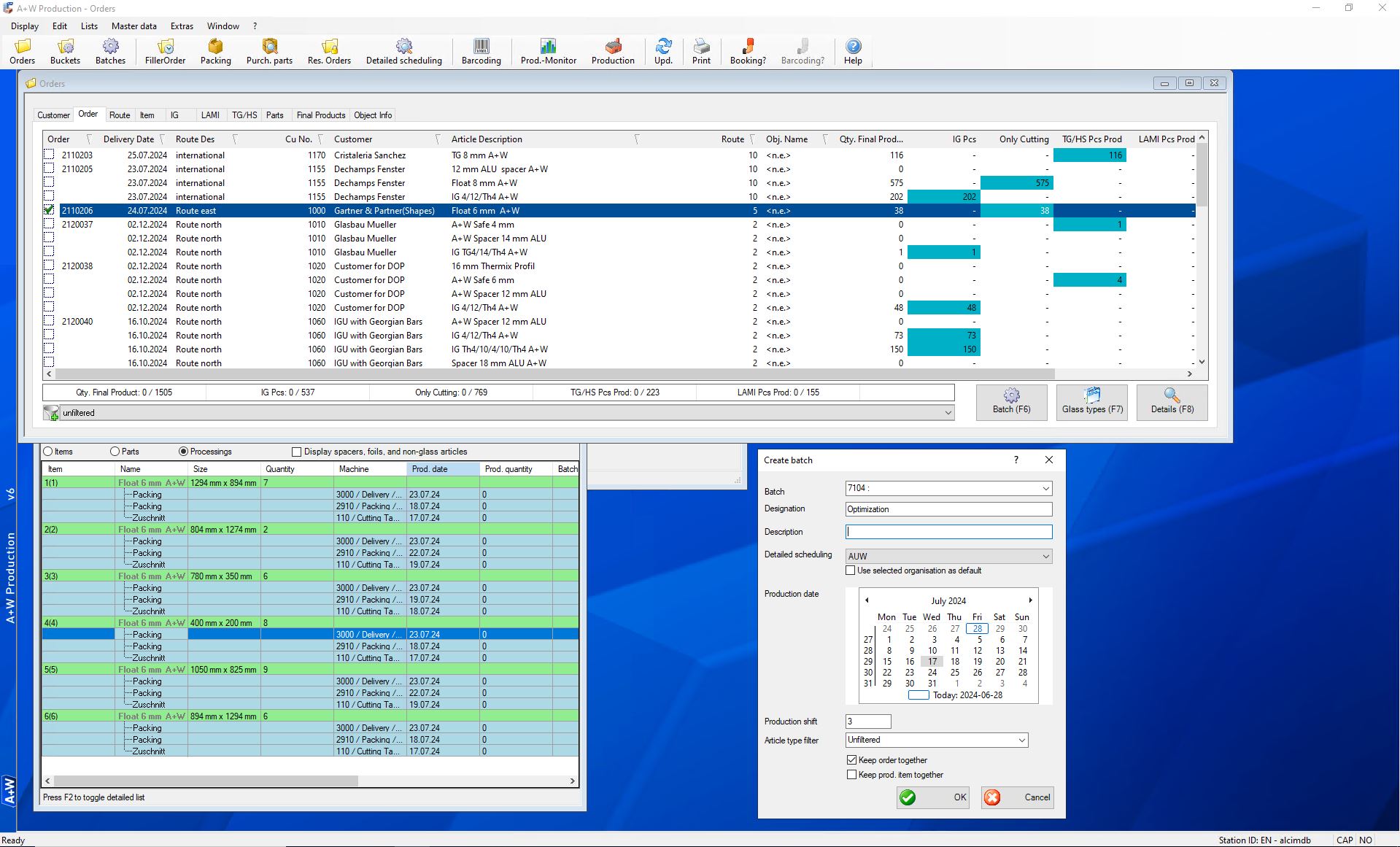

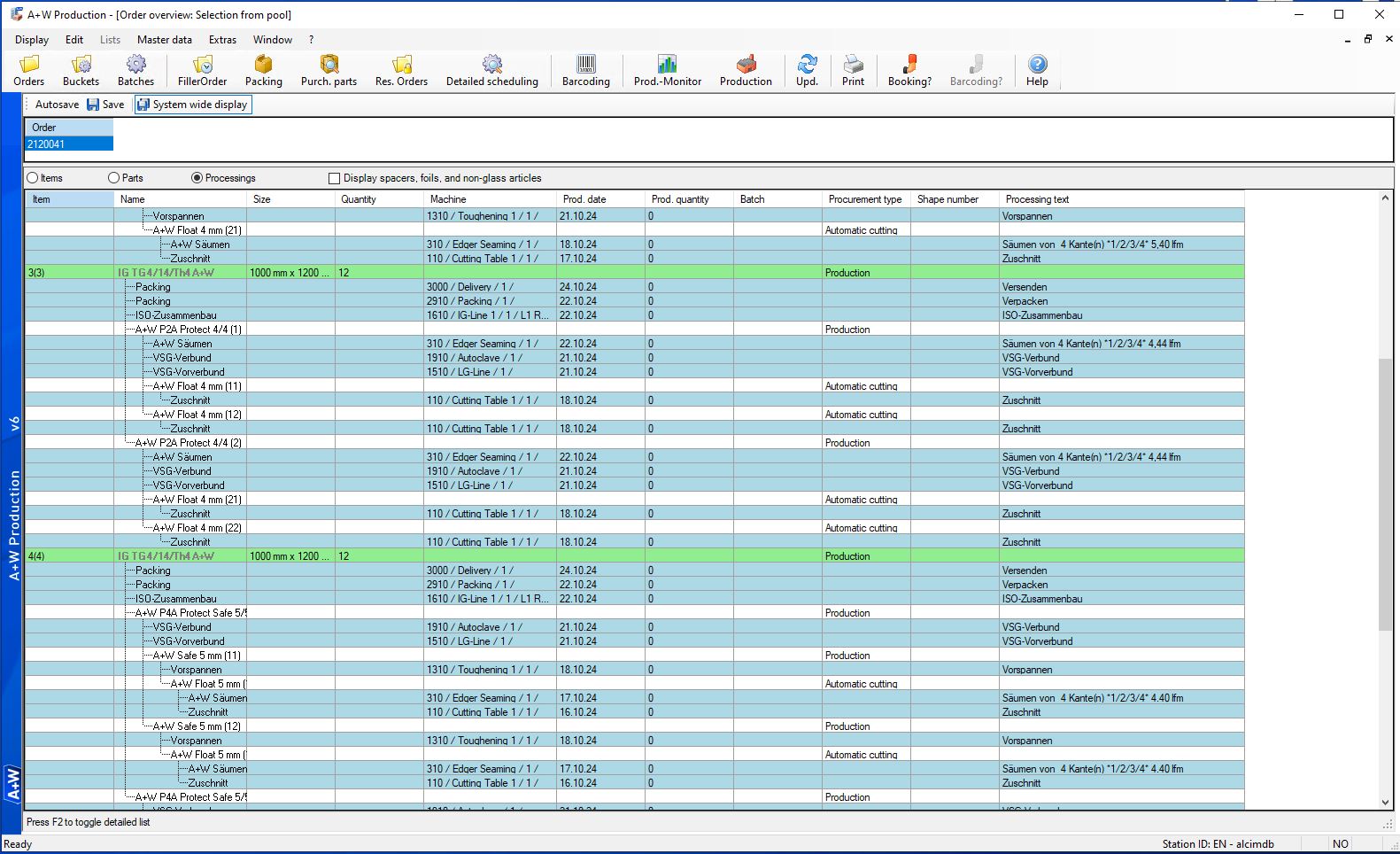

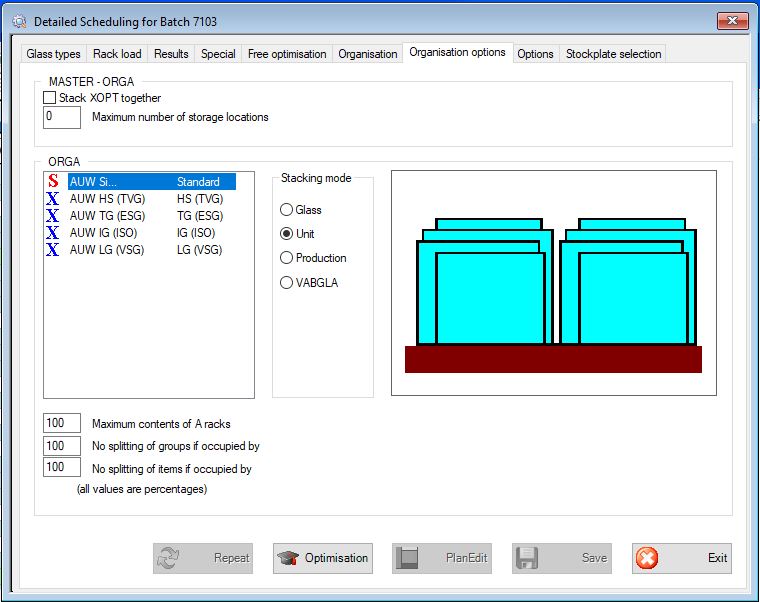

In conjunction with a more streamlined production process, you’ll find our software solution also flexibly configures production planning with various constraints, such as machines and processing sequences, all in an effort to improve your processes. Our software solution ensures optimized control over production batches, racks, and storage locations, employing state-of-the-art algorithms for precise waste optimization.

A+W Production offers flexibility and scalability, suitable for both small and large production environments. Compatible with various ERPs, it seamlessly integrates into existing systems, providing comprehensive production optimization solutions.

Unique cutting optimization algorithms guarantee maximum efficiency. Integration of capacity planning and production data acquisition enhances production control and processes.

Want to do more with A+W Production? Connect it to module extensions, such as the A+W Capacity Planner, A+W Barcode Manager, or A+W Production Terminal, which allow the system to scale and meet your newest needs and goals, so that the system grows with your company.

Functionalities and Benefits

- Plan and control production utilizing various restrictions, including machines, process sequences, etc.

- Quickly and easily manage orders and batches

- Optimize yield with state-of-the-art algorithms

- Sequence optimization as well as rack and storage space organization and optimization

- Optimization directly on racks and in boxes in shipping sequence (Software Module Extension: A+W Rack Optimizer)

- Visualization and modification of the cutting plan

- Simple machine management and direct machine control

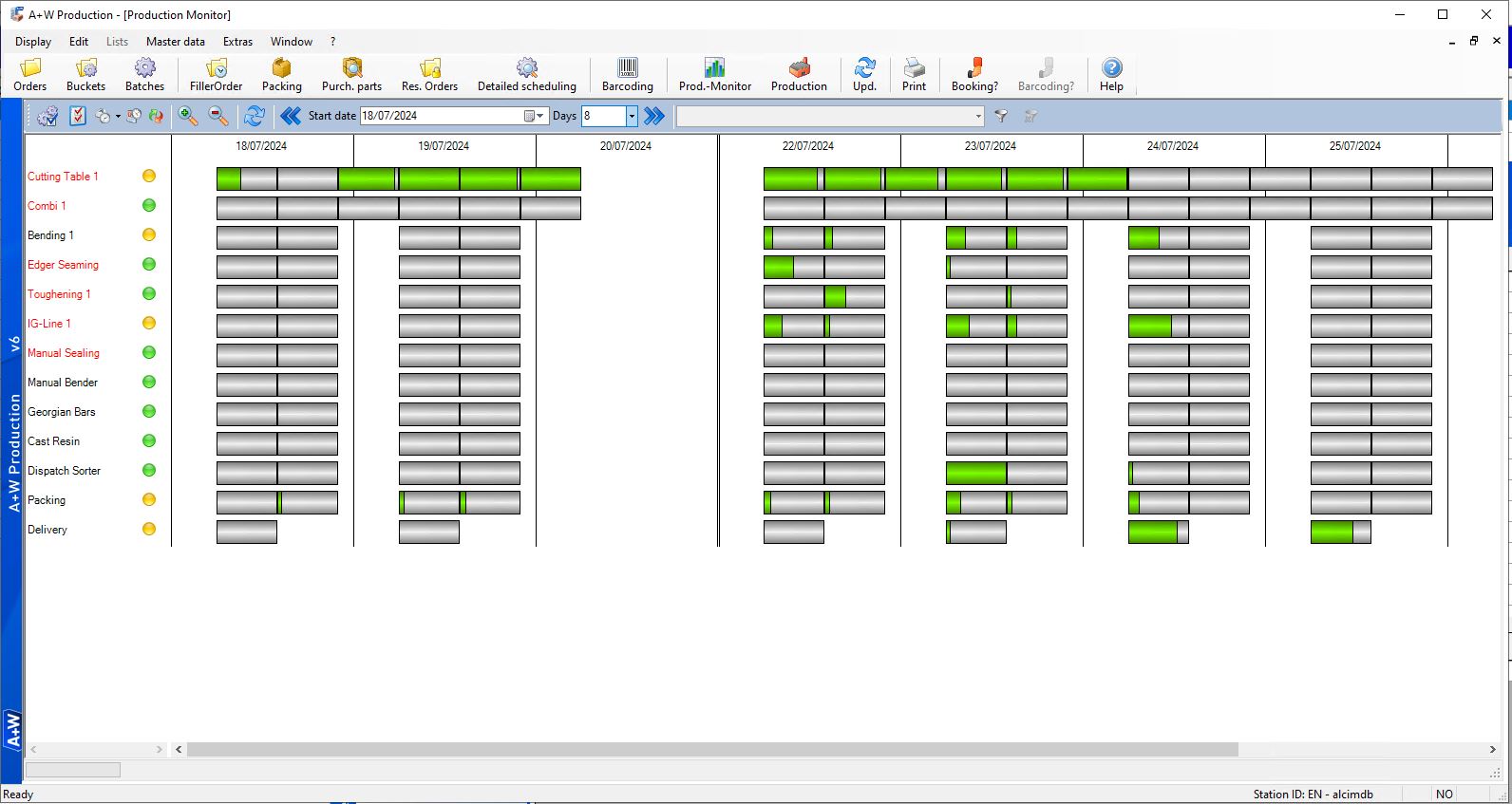

- Efficient and graphical capacity planning (Software Module Extension: A+W Capacity Planner)

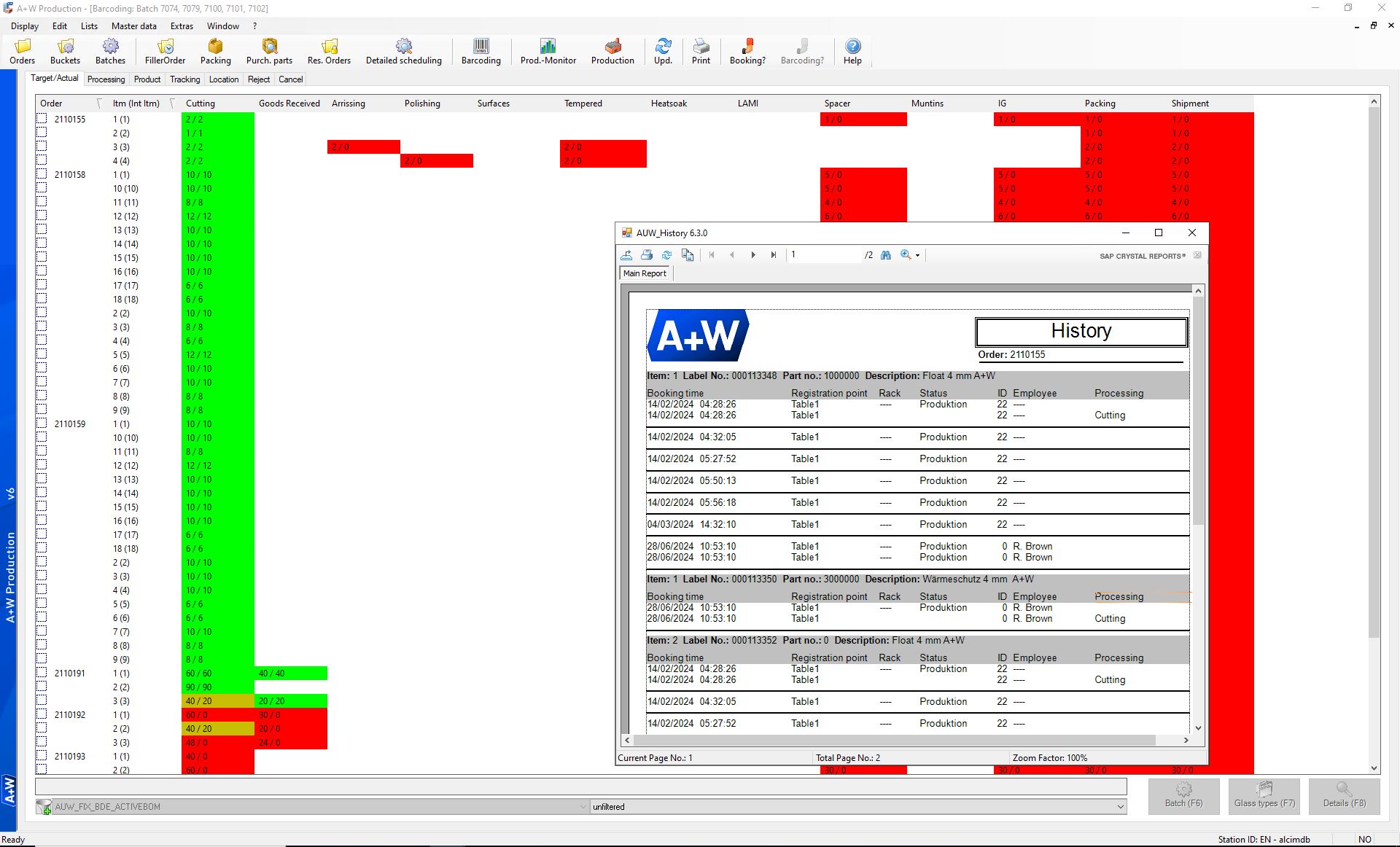

- Full integration of PDA and tracking (Software Module Extension: A+W Barcode Manager)

- Up-to-date statistics thanks to Crystal Reports and QLIK

- Printout production documents, bending texts, and barcode labels

With A+W Production, you have access to the latest production data and its current status allowing you to quickly react to changes and continuously improve. This software solution offers you a wide range of evaluation options to analyze and optimize your production processes.

Want to find out more about A+W Production? We will be happy to answer your questions and advise you on the best software solutions for your company.

Satisfied Customer Voices

A+W Clarity Reference

Flachglas Schweiz

With A+W Production, we can plan and conduct our production much more efficiently, especially in the interplay with production control and completion reporting by plant data collection. Currently, we are working with A+W on the implementation of a breakage pool, with which we can reproduce defective lites quickly.

Read more

A+W Clarity Reference

Semcoglas Glastechnik

The staff is not supposed to run around the shop floor to gather information but they shall have all the information they need for the production step on hand right at their workstation.

Read more

A+W Clarity Reference

Glas Herzog

A+W Business 6 is the best version of the commercial A+W software. The system works reliably, and thanks to the BOM concept, all products can be mapped. And if something gets hung up, A+W offers reliable service – our contact people, with whom we have been working for years, are experts, they help us quickly and easily.

Read more

Popular Add-ons

Clarity

Capa View

Interested in monitoring your production capacity utilization or tracking the progress of individual orders and batches? A+W Capa View provides immediate access to production status information, while also seamlessly connecting to A+W Barcode Manager and/or Production Terminal for real-time updates.

A+W Capa View has a user-friendly interface offers clear and concise displays of production data, with detailed information available that’s just a double-click away. Customize views based on shifts or daily operations, and configure them according to your preferences.

A+W Capa View’s standout feature lies in its customizability, allowing real-time utilization overviews and views of configurable machine groups for enhanced production control.

- Status information per order and/or per batch

- Strong interconnection with A+W Barcode Manager and/or Production Terminal

- Individualized adjustable information display, e.g., shift-based vs. daily information

- Production completion feedback

- Integrated in A+W Business or stand-alone in order entry

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Clarity

DynOpt

A+W DynOpt revolutionizes the glass production process by leveraging advanced functions and state-of-the-art technologies that streamline operations. Through automatic linking and mixing of cutting orders, flexible input of residual sheets and stock glass as well as dynamic adjustment of glass types and stock sizes, A+W DynOpt ensures a seamless production process and optimum material utilization.

A notable feature of A+W DynOpt is its capability to integrate glass cutting lines using sorting systems, such as the Lisec buffer and sorting system or Hegla SortJet, with downstream stacking stations or directly connected production lines. It offers fully automated optimization, cutting, and sorting processes for maximum yield while maintaining the desired production sequences. By reducing breakage rejects and enhancing quality, A+W DynOpt, delivers unparalleled efficiency and quality.

The software solution synchronizes multiple cutting tables, enabling simultaneous cutting and breaking of diverse glass types while facilitating automatic load distribution across production lines. Its dynamic optimization algorithm reacts to sorting buffer levels, eliminating the need for extensive sorting systems and allowing for batch sizes of any scale

A+W DynOpt’s key strengths lie in its dynamic nature, ensuring optimal material flow and balanced distribution between cutting and further processing steps.

These strengths eliminate manual steps between cutting and further processing. With enhanced automation and flexibility in planning, whether for individual or daily production, and maximum material yield through the use of a buffer, A+W DynOpt sets new benchmarks in glass production efficiency.

- Fully automated optimization, cutting, and sorting, including recutting of broken slices

- Automatic linking and mixing of cutting jobs for seamless production

- Automatic & flexible input of residual plates and stock sheets

- Dynamic and flexible modification of glass types and stock sizes

- Controls residual stock (e.g. Hegla Remaster)

- Controlled output into one or more harp racks, or directly to one or more IG lines

- Synchronization of multiple cutting tables – enables cutting and breaking of multiple glass types simultaneously

- Automatic load distribution across several production lines for optimized efficiency

- Rush lite /orders are given higher priority for timely processing

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

A+W Business 6 is the best version of the commercial A+W software. The system works reliably, and thanks to the BOM concept, all products can be mapped. And if something gets hung up, A+W offers reliable service – our contact people, with whom we have been working for years, are experts, they help us quickly and easily.

Project implementation was usually more complicated than we would have thought, but everything always went well in the end (…) I don’t know of any better optimization solutions.

Clarity

Rack Optimizer

A+W Rack Optimizer transforms the packaging process in insulating glass production by enabling direct packaging and maximing the utilization of packaging materials. This ensures consistent packaging quality, while reducing reliance on employee expertise.

The software considers unloading sequences and allows for customized sequencing to balance weight and optimize rack loading/unloading, minimizing the needs for order picking and reducing transport costs A 3D visualization provides detailed previews and graphic instructions for packaging optimization.

- Increasing productivity on the IG line, addressing bottlenecks

- Eliminate re-sorting requirements in dispatch

- Potential use of robots for stacking and packaging

- Reduced breakage and rejects through automated glass packaging

- Automatic weight balancing and limit check for packing racks

- 3D pack view for detailed rack loading visualization and item identification

- Manual lite movement using the 3D pack view editor

- Special mode for cases

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Standalone

Solutions without ERP system

Clarity

Smart Companion

The A+W Smart Companion revolutionizes warehouse management and logistics in the glass industry through its versatile functions and user-friendly handling. This innovative solution is usable on a mobile device under iOS and Android, offering an intuitive menu navigation that enables easy operation. The A+W Smart Companion can be deployed on various smart devices according to requirements and offers the ability to scan multiple barcodes in continuous mode.

Supporting the entire value chain, the A+W Smart Companion contributes to its digitization, saving time and costs while making processes more flexible. Warehouse management can be digitized with the A+W Smart Companion Stock Module, allowing the use of smart devices as scanner hardware for capturing inputs, outputs, transfers, and changes. During inventory, the Inventory function of the warehouse module supports the process with useful filters, checklists, and dashboards to optimize and simplify the process.

- Runs under iOS and Android

- User-friendly menu guide

- Depending on requirements, can be used on different smart devices

- Scanning of several bar codes in continuous mode

- Continuous digital stock management

- Safe and secure inventory

- Record incoming goods and stock transactions quickly and without errors

- more efficient workflows, no unnecessary running around

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.