Production

Perfect production planning for optimized processes

Scalable

Suitable for small to large production facilities

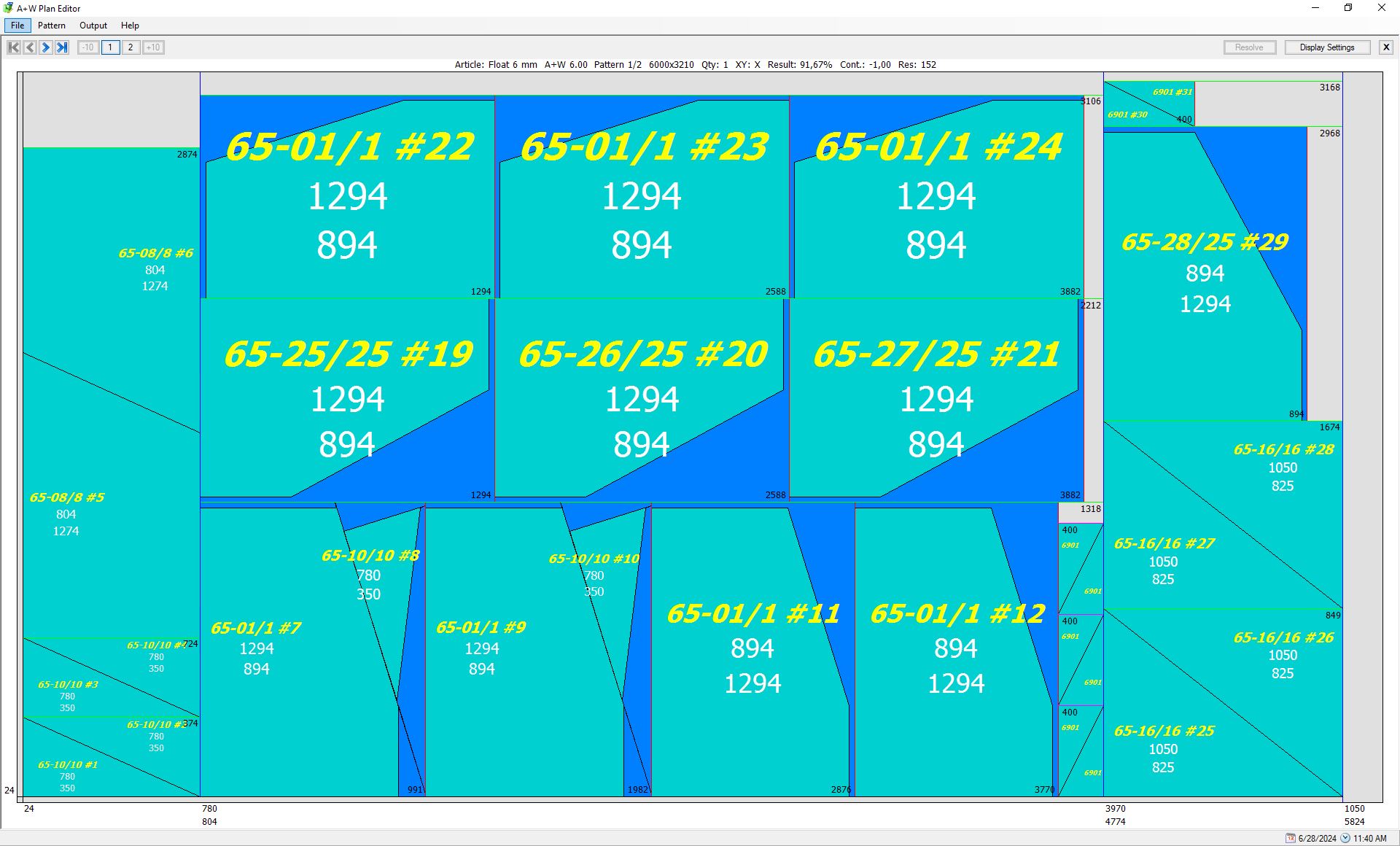

Cutting optimization

Great optimization thanks to smart algorithms

Compatible

Linkable to external ERP systems

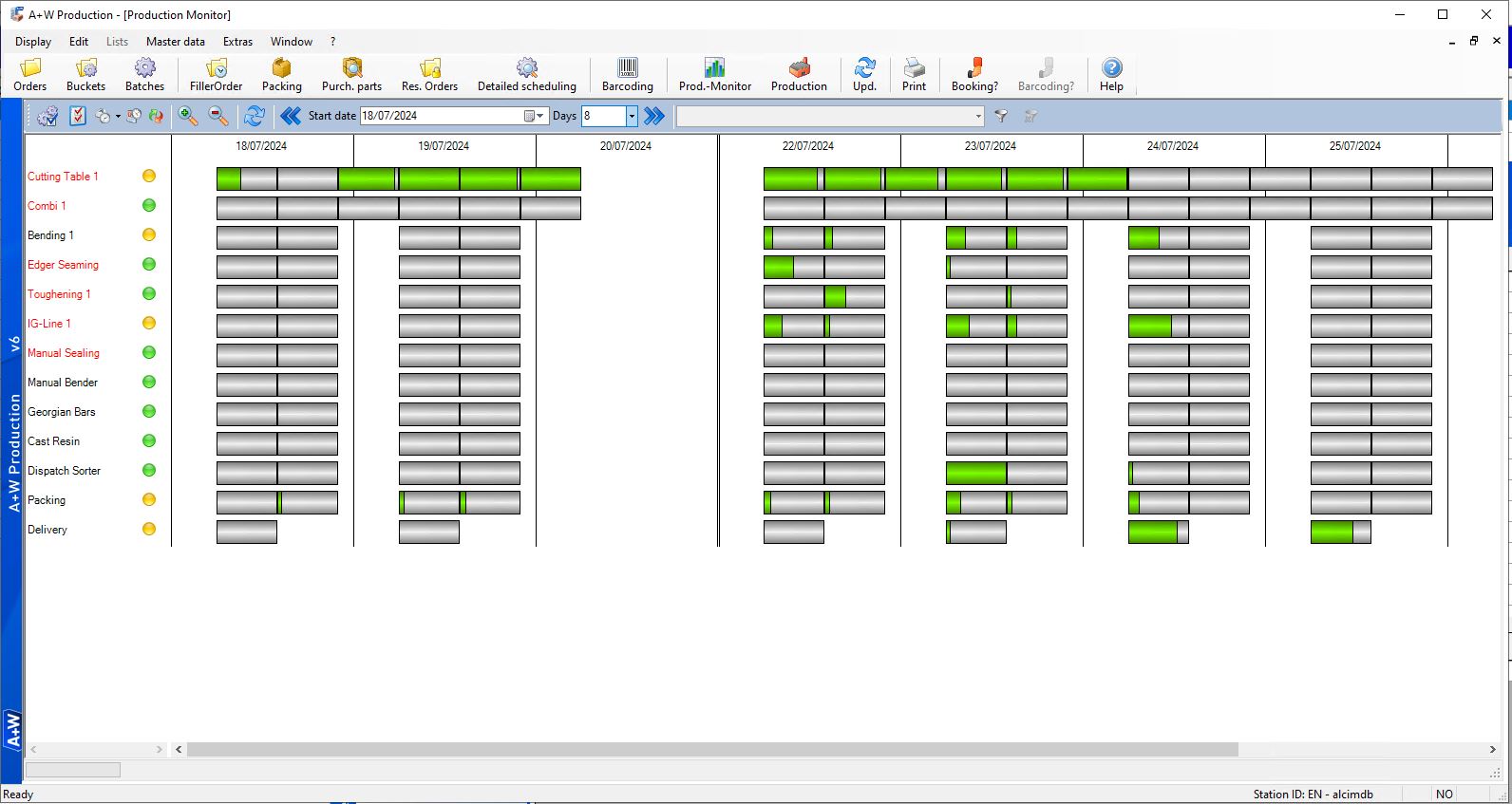

Higher-level process optimization

Combined packaging optimization

About the Product

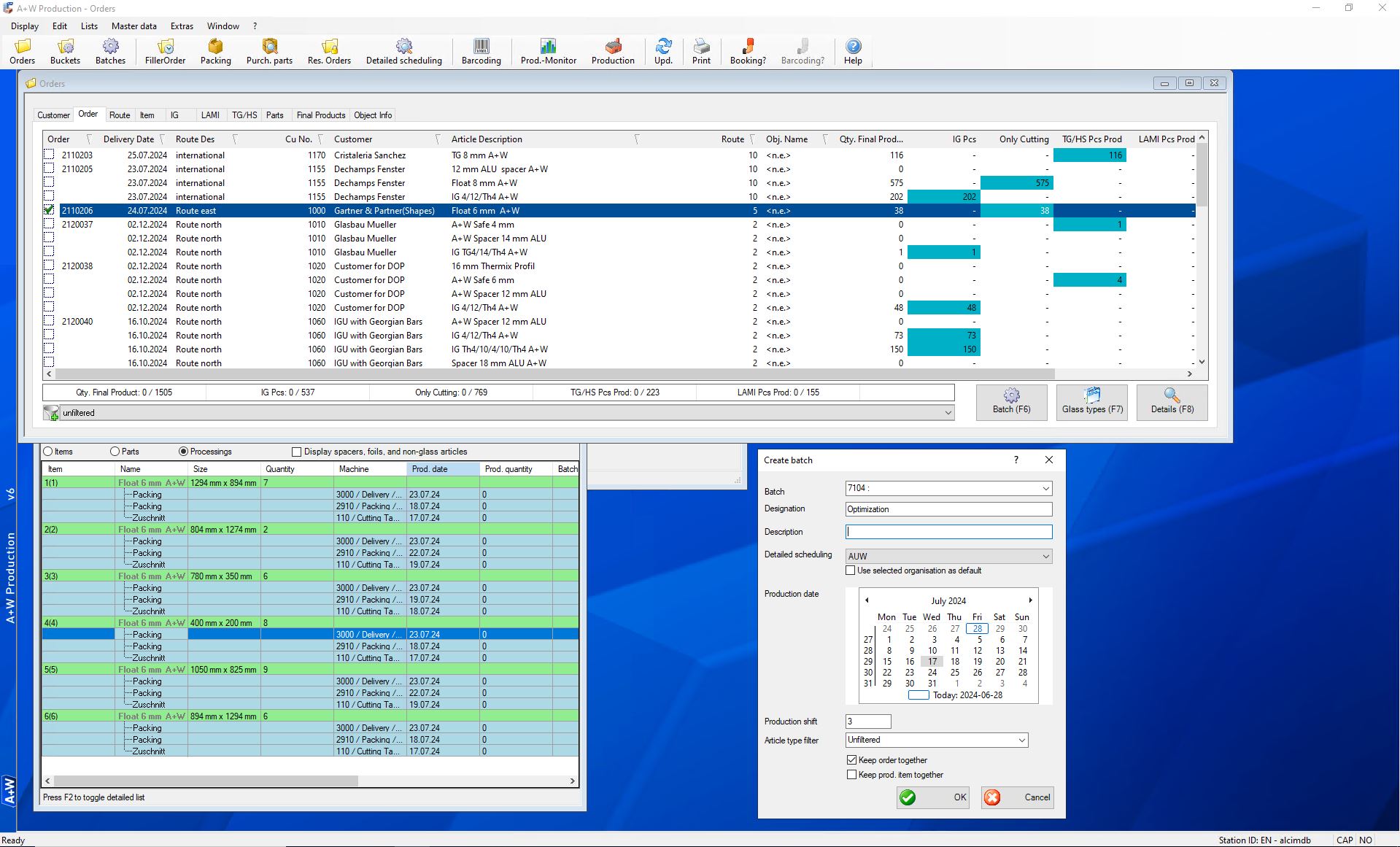

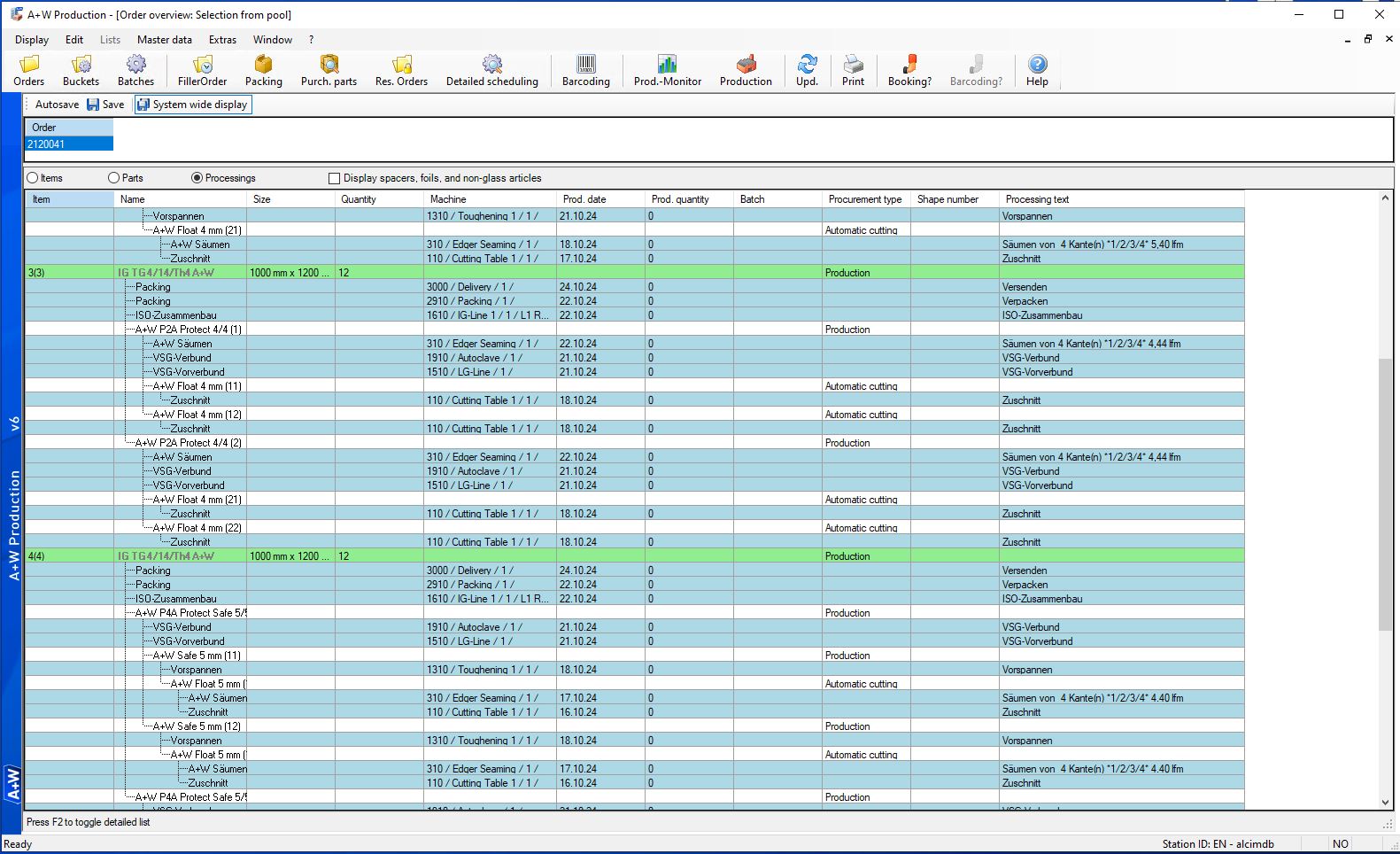

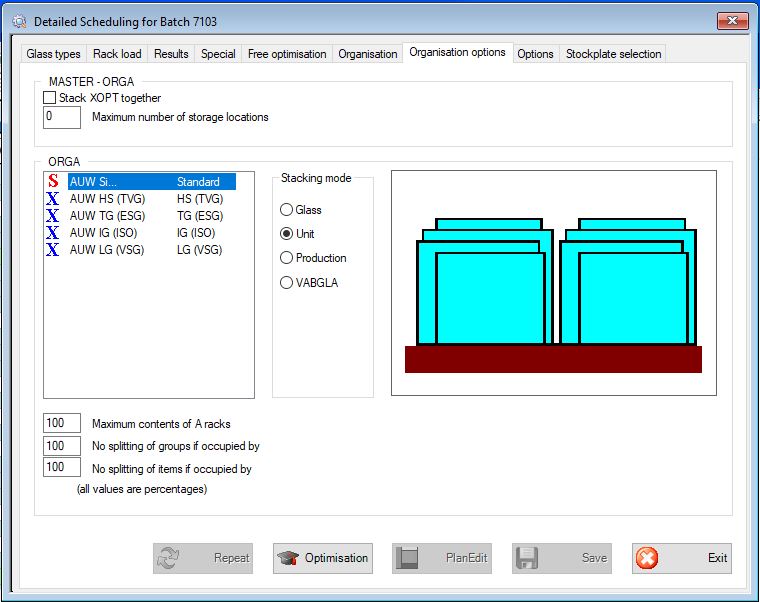

In conjunction with a more streamlined production process, you’ll find our software solution also flexibly configures production planning with various constraints, such as machines and processing sequences, all in an effort to improve your processes. Our software solution ensures optimized control over production batches, racks, and storage locations, employing state-of-the-art algorithms for precise waste optimization.

A+W Production offers flexibility and scalability, suitable for both small and large production environments. Compatible with various ERPs, it seamlessly integrates into existing systems, providing comprehensive production optimization solutions.

Unique cutting optimization algorithms guarantee maximum efficiency. Integration of capacity planning and production data acquisition enhances production control and processes.

Want to do more with A+W Production? Connect it to module extensions, such as the A+W Capacity Planner, A+W Barcode Manager, or A+W Production Terminal, which allow the system to scale and meet your newest needs and goals, so that the system grows with your company.

Functionalities and Benefits

- Plan and control production utilizing various restrictions, including machines, process sequences, etc.

- Quickly and easily manage orders and batches

- Optimize yield with state-of-the-art algorithms

- Sequence optimization as well as rack and storage space organization and optimization

- Optimization directly on racks and in boxes in shipping sequence (Software Module Extension: A+W Rack Optimizer)

- Visualization and modification of the cutting plan

- Simple machine management and direct machine control

- Efficient and graphical capacity planning (Software Module Extension: A+W Capacity Planner)

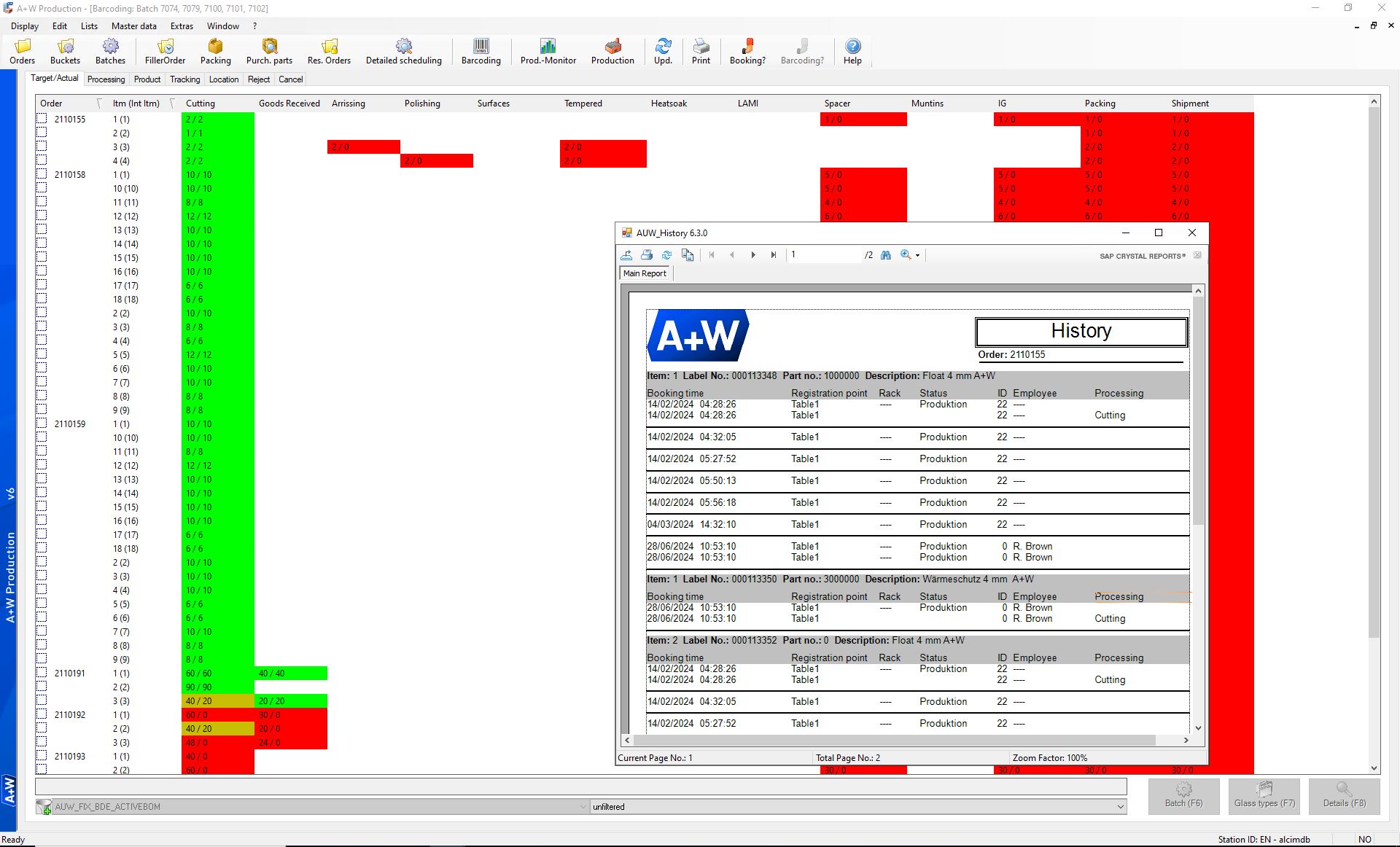

- Full integration of PDA and tracking (Software Module Extension: A+W Barcode Manager)

- Up-to-date statistics thanks to Crystal Reports and QLIK

- Printout production documents, bending texts, and barcode labels

With A+W Production, you have access to the latest production data and its current status allowing you to quickly react to changes and continuously improve. This software solution offers you a wide range of evaluation options to analyze and optimize your production processes.

Want to find out more about A+W Production? We will be happy to answer your questions and advise you on the best software solutions for your company.

Satisfied Customer Voices

A+W Clarity Reference

BarteltGLASBerlin

The future is not something you have, it’s something you make!

Read more

A+W Clarity Reference

Reflex

My father always used to strive for the optimum production solution. This also applies to the software we are using. We have therefore been using A+W software for more than 30 years, and have never looked back. Another important criterion for us is service. At A+W, this is solution-oriented; their experts know their job and communicate excellently with our staff and machinery partners.

Read more

A+W Clarity Reference

Glas Schöninger

The A+W Barcode Tracking has taken our entire production organization to a new performance level. Only with it are we in a position to truly organize ourselves efficiently without long information paths, complicated inquiries, and time-consuming re-makes. Earlier, an employee frequently had to search for racks for hours in order to find a sheet if he was not sure whether or not it had been produced yet. Today, he just looks in the system – done!

Read more

Popular Add-ons

Clarity

Production Terminal

A+W Production Terminal transforms production processes within the glass industry by utilizing robust capabilities and an user-friendly interface. This software solution facilitates interactive process visualization, real-time production data acquisition, and seamless control.

One notable feature the A+W Production Terminal is its ability to visualize pane setups, dimensions and processing steps, and provide employees with a clear overview of ongoing processes that require immediate intervention when necessary. Additionally, each terminal supports the display of CAD drawings and document links, which enhance communication and collaboration throughout production.

The integration of A+W Barcode Manager with the A+W Production Terminal is another key aspect, enabling efficient booking of breakage slices and reasons, along with machine status feedback and automatic scrap handling, which collectively enhances productivity, efficiency and processing quality.

- Visualize pane structures, dimensions, and processing steps

- Display of CAD drawings

- Document links for enhanced communication and collaboration

- Booking of breakage and reason

- Booking and feedback of machine status

- Automatic reject handling with implemented downstream concept

- Fully customizable user interface

- Control via foot panel for convenient operation

- Display rack information for subsequent processes

- Online printing of labels

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

The A+W Barcode Tracking has taken our entire production organization to a new performance level. Only with it are we in a position to truly organize ourselves efficiently without long information paths, complicated inquiries, and time-consuming re-makes. Earlier, an employee frequently had to search for racks for hours in order to find a sheet if he was not sure whether or not it had been produced yet. Today, he just looks in the system – done!

My father always used to strive for the optimum production solution. This also applies to the software we are using. We have therefore been using A+W software for more than 30 years, and have never looked back. Another important criterion for us is service. At A+W, this is solution-oriented; their experts know their job and communicate excellently with our staff and machinery partners.

Clarity

Dashboard

With A+W Dashboard, you gain a clear overview of key production metrics, allowing swift responses to machine and work bottlenecks. Its graphical presentation of production data facilitates intuitive monitoring, while also allowing desktop PCs, tablets, or smartphones access to information anytime, anywhere.

Our modern and simple HTML configurator enables personalized views, adaptable to various devices, ensuring convenient access to data from the past 24 hours to real-time updates. Fully integrated with A+W Production, A+W’s Dashboard provides key performance indicators derived from PDA postings, which is then augmented by statistical insights from BI tools for comprehensive control.

Unique features of A+W Dashboard include machine performance overview, which displays booking data per machine, and mobile accessibility, allowing you to set target values for performance assessment. The visualization of data makes setting target values for success easier.

- Graphical representation of KPIs

- Real-time detection of bottlenecks for production control and high information density for comprehensive insights

- Modern and simple HTML configurator for personalized views

- Compatible across desktop and mobile devices

- Seamless integration with A+W Production for enhanced performance tracking, including KPIs based on barcoding bookings

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Clarity

Capa View

Interested in monitoring your production capacity utilization or tracking the progress of individual orders and batches? A+W Capa View provides immediate access to production status information, while also seamlessly connecting to A+W Barcode Manager and/or Production Terminal for real-time updates.

A+W Capa View has a user-friendly interface offers clear and concise displays of production data, with detailed information available that’s just a double-click away. Customize views based on shifts or daily operations, and configure them according to your preferences.

A+W Capa View’s standout feature lies in its customizability, allowing real-time utilization overviews and views of configurable machine groups for enhanced production control.

- Status information per order and/or per batch

- Strong interconnection with A+W Barcode Manager and/or Production Terminal

- Individualized adjustable information display, e.g., shift-based vs. daily information

- Production completion feedback

- Integrated in A+W Business or stand-alone in order entry

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Clarity

CAD Designer

Looking for a CAD system designed specifically for the flat glass industry? Look no further than A+W CAD Designer, which offers innovative design solutions. With intuitive tools, it facilitates the creation of complex free forms and standard templates for reuse in ERP systems.

The special challenge of free-form entry of construction and automobile glass is entering the multitude of parameters quickly and correctly, drawing technically correctly and clearly, and generating reliable CNC code from this.

The A+W CAD Designer enables the entry of lite and contour data, all processings, the takeover of customer CAD data and the digitalization of templates, for example via digitalization table or virtual digitizing.

Moreover, A+W CAD Designer has a bar design program with graphical interface that allows the majority of common bar types to be arranged at will on a rectangular or shaped lite. Bars of different widths can be used in a design, and it is also possible to use different bar types within a bar pattern.

- Simple and quick creation of complex individual shapes and standard template files for re-use in ERP systems

- Easily capture and modify complex shapes and processing steps, such as edge layering or intricate cut-outs

- Correct inaccuracies in digitized shapes using A+W's patented streaming mode

- Easy entering and changing of difficult shapes and processings (for example edge deletion or complex cut-outs)

- Possibility of direct control of your CNC machine

- Easy and quick creation and dimensioning of complex grill pattern designs

- Little training required thanks to graphical tools and modern user guidance

- Direct control of the muntin saw possible

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

I love the innovation I see at A+W. Ideas that promote continuous improvement will move the industry ahead.

We’ve not missed a beat. June 2020 was the biggest month we’ve ever had in our history. We keep humming along.