Software Solutions

Take your ERP system to the next level!From optimizations in the production environment to supporting your employees during transport and stock management, our add-ons deliver valuable functions tailored to your needs.

Barcode Manager

Shop Floor Solutions

Business

Business Pro

Production

CAD Designer

Office Solutions

Business

Business Pro

Enterprise

Production

Capa View

Office Solutions

Shop Floor Solutions

Business

Production

Capacity Planner

Shop Floor Solutions

Business Pro

Production

Dashboard

Shop Floor Solutions

Production

Defect Optimizer

Shop Floor Solutions

Production

DynOpt

Shop Floor Solutions

Production

Furnace Optimizer

Shop Floor Solutions

Business

Business Pro

Enterprise

Production

iQuote

Office Solutions

Business

Business Pro

Enterprise

iShape

Mobile Solutions

Office Solutions

Business

Business Pro

Enterprise

Production

Logistics Optimizer

Logistics Solutions

Business

Business Pro

Enterprise

Production Terminal

Shop Floor Solutions

Production

Rack Optimizer

Shop Floor Solutions

Production

Standalone

Realtime Optimizer

Shop Floor Solutions

Production

Standalone

Shape Optimizer

Shop Floor Solutions

Business Pro

Production

Smart Companion

Mobile Solutions

Warehouse Solutions

Business

Enterprise

Production

Smart Delivery Maps

Logistics Solutions

Mobile Solutions

Business

Business Pro

Enterprise

Barcode Manager

Barcode scanning and tracking saves your employees and company time and money! A+W offers a wide array of functions to streamline production and process oversight.

Take charge of processing steps, keep track of machine utilization, and also record any breakage with ease using A+W’s barcode solution. This solution lays the groundwork for comprehensive evaluations and future planning, which are vital to your company’s current and future success. From status and storage location bookings (per user, station, machine, rack, item, and sheet) to precise processing entries and machine control via barcode scanning, our solution was designed to specifically meet your needs.

- Status and location bookings per user, station/machine, rack, item & sheet

- Machine start and control of processing via barcode reading

- Automatic reject handling (with implemented downstream concept)

- Statistical evaluations based on barcode readings (e.g. by using Crystal Reports or QLIK)

- Quality improvements based on breakage bookings

- Capacity updates based on barcode readings

- Printout of labels by A+W Production

- Flexible label design thanks to CR

- Centralized display of status information based on barcode readings by extension A+W Production Monitor and/or A+W Production Terminals

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

The A+W software controls and checks all processes from entry of the order to control of the machines, on through to delivery of the finished products. Thanks to consistent barcode control and the A+W Production Monitors, we always know where each sheet is at any point in time. All commercial and technical data is available company-wide – and this without having employees running around all the time with folders and stacks of paper under their arms in order to determine what they must do with which sheet (…) All employees work productively! The focus is always on information, all the time and everywhere.

In addition to the quality of the software, the implementation and maintenance of such a system requires a strong, steady partner with experienced specialists who can react quickly and solve even difficult problems reliably. This is where our trust in A+W paid off completely. A+W software is a strong product, behind which there is a strong, innovative company. This is why we have satisfied customers and low complaint rates.

CAD Designer

Looking for a CAD system designed specifically for the flat glass industry? Look no further than A+W CAD Designer, which offers innovative design solutions. With intuitive tools, it facilitates the creation of complex free forms and standard templates for reuse in ERP systems.

The special challenge of free-form entry of construction and automobile glass is entering the multitude of parameters quickly and correctly, drawing technically correctly and clearly, and generating reliable CNC code from this.

The A+W CAD Designer enables the entry of lite and contour data, all processings, the takeover of customer CAD data and the digitalization of templates, for example via digitalization table or virtual digitizing.

Moreover, A+W CAD Designer has a bar design program with graphical interface that allows the majority of common bar types to be arranged at will on a rectangular or shaped lite. Bars of different widths can be used in a design, and it is also possible to use different bar types within a bar pattern.

- Simple and quick creation of complex individual shapes and standard template files for re-use in ERP systems

- Easily capture and modify complex shapes and processing steps, such as edge layering or intricate cut-outs

- Correct inaccuracies in digitized shapes using A+W's patented streaming mode

- Easy entering and changing of difficult shapes and processings (for example edge deletion or complex cut-outs)

- Possibility of direct control of your CNC machine

- Easy and quick creation and dimensioning of complex grill pattern designs

- Little training required thanks to graphical tools and modern user guidance

- Direct control of the muntin saw possible

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

I love the innovation I see at A+W. Ideas that promote continuous improvement will move the industry ahead.

The [A+W] team made a serious and dedicated effort to fix things. And they incorporated new tools like barcode scanning, seeing the product, [and] production scheduling [all of which have] really helped us improve our On-time in Full (OTIF) number.

Capa View

Interested in monitoring your production capacity utilization or tracking the progress of individual orders and batches? A+W Capa View provides immediate access to production status information, while also seamlessly connecting to A+W Barcode Manager and/or Production Terminal for real-time updates.

A+W Capa View has a user-friendly interface offers clear and concise displays of production data, with detailed information available that’s just a double-click away. Customize views based on shifts or daily operations, and configure them according to your preferences.

A+W Capa View’s standout feature lies in its customizability, allowing real-time utilization overviews and views of configurable machine groups for enhanced production control.

- Status information per order and/or per batch

- Strong interconnection with A+W Barcode Manager and/or Production Terminal

- Individualized adjustable information display, e.g., shift-based vs. daily information

- Production completion feedback

- Integrated in A+W Business or stand-alone in order entry

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Capacity Planner

A+W Capacity Planner provides a comprehensive overview of your production facilities’ available capacities and their utilization, which empowers you to effectively plan your production. This software solution also allows you to easily manage shifts, capacities, bottlenecks, and workloads for efficient processes.

This software offers flexibility in defining machine and operation restrictions, while also automatically adjusting production dates if capacities are insufficient. You can also calculate delivery dates, processing timelines, and costs effortlessly, while distributing loads across machines.

With A+W Capacity Planner, you can optimize production progress and costs by considering fixed processing times and campaign planning. By taking this information into account, you can reserve capacities and prioritize customer groups for streamlined order processing. Additionally, you can maintain control with detailed production progress displays and integration with A+W Barcode Manager and/or A+W Production Terminals. By being able to scale and combine A+W modules, you have more control and understand of every process in your facility.

- Display machine capacities and utilization information

- Easy management of shifts, capacities, bottlenecks and workload

- Free, formula-based machine and work process restrictions

- Automatically transfer production dates when capacity is insufficient at dispatch

- Calculate delivery dates and processing timelines

- Automatic calculation processing dates, durations and costs during import

- Automatic load distribution on machines based on work processes

- Cost calculation for orders and quotes

- Management of reservations and campaigns

- Directly communicate information to the ERP system

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Thanks to A+W Production and A+W Barcoding, the shop floor as well as the A+W Business order processing system know the processing status of every sheet, any time. The staff can answer customers’ enquiries right away on the phone – our customers appreciate this!

With A+W iQuote, anything that is ordered can actually be built. The entire order runs through a restriction check based on master data stored in A+W Business. The customer transmits a technically correct complete order to us. There are no questions and time-consuming clarifications by telephone or e-mail. This is how we can achieve much greater efficiency in the entire order process.

Dashboard

With A+W Dashboard, you gain a clear overview of key production metrics, allowing swift responses to machine and work bottlenecks. Its graphical presentation of production data facilitates intuitive monitoring, while also allowing desktop PCs, tablets, or smartphones access to information anytime, anywhere.

Our modern and simple HTML configurator enables personalized views, adaptable to various devices, ensuring convenient access to data from the past 24 hours to real-time updates. Fully integrated with A+W Production, A+W’s Dashboard provides key performance indicators derived from PDA postings, which is then augmented by statistical insights from BI tools for comprehensive control.

Unique features of A+W Dashboard include machine performance overview, which displays booking data per machine, and mobile accessibility, allowing you to set target values for performance assessment. The visualization of data makes setting target values for success easier.

- Graphical representation of KPIs

- Real-time detection of bottlenecks for production control and high information density for comprehensive insights

- Modern and simple HTML configurator for personalized views

- Compatible across desktop and mobile devices

- Seamless integration with A+W Production for enhanced performance tracking, including KPIs based on barcoding bookings

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Defect Optimizer

Do your customers complain about faulty sheets/windows after installation? If you’re dealing with customer complaints about faulty glass or spending resources on reproducing units due to defects, then you have already incurred considerable costs in producing (and shipping) the sheet. And now you are investing again to reproduce a sheet and, if necessary, send it to the customer again.

Why not detect the defects before cutting and take them into account during optimization?

A+W Defect Optimizer detects defects before cutting, saving you time and money. With statistically only 0.6 defects per jumbo, it identifies and corrects defects by rearranging sheets to maintain the overall sequence. In cases where defects are unavoidable, A+W Defect Optimizer offers a cost-effective solution by cutting small, low-cost sheets for defects and automatically recutting them. Defects on remaining sheets are saved, so they do not need to be detected again when used.

- Early detection of errors in the production chain

- Error detection, error correction, error prevention: optimization takes errors per jumbo into account, rearranges lites and attempts to maintain the overall sequence

- If errors cannot be avoided - small (cheap) lites for errors + automatic remakes

- Defects are saved for remaining sheets - no additional detection necessary!

- Integration with quality scanners for accurate defect detection or based on the coordinates from your supplier

- Real-time optimization to recalculate the existing results

- Machine control updates during cutting process

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

DynOpt

A+W DynOpt revolutionizes the glass production process by leveraging advanced functions and state-of-the-art technologies that streamline operations. Through automatic linking and mixing of cutting orders, flexible input of residual sheets and stock glass as well as dynamic adjustment of glass types and stock sizes, A+W DynOpt ensures a seamless production process and optimum material utilization.

A notable feature of A+W DynOpt is its capability to integrate glass cutting lines using sorting systems, such as the Lisec buffer and sorting system or Hegla SortJet, with downstream stacking stations or directly connected production lines. It offers fully automated optimization, cutting, and sorting processes for maximum yield while maintaining the desired production sequences. By reducing breakage rejects and enhancing quality, A+W DynOpt, delivers unparalleled efficiency and quality.

The software solution synchronizes multiple cutting tables, enabling simultaneous cutting and breaking of diverse glass types while facilitating automatic load distribution across production lines. Its dynamic optimization algorithm reacts to sorting buffer levels, eliminating the need for extensive sorting systems and allowing for batch sizes of any scale

A+W DynOpt’s key strengths lie in its dynamic nature, ensuring optimal material flow and balanced distribution between cutting and further processing steps.

These strengths eliminate manual steps between cutting and further processing. With enhanced automation and flexibility in planning, whether for individual or daily production, and maximum material yield through the use of a buffer, A+W DynOpt sets new benchmarks in glass production efficiency.

- Fully automated optimization, cutting, and sorting, including recutting of broken slices

- Automatic linking and mixing of cutting jobs for seamless production

- Automatic & flexible input of residual plates and stock sheets

- Dynamic and flexible modification of glass types and stock sizes

- Controls residual stock (e.g. Hegla Remaster)

- Controlled output into one or more harp racks, or directly to one or more IG lines

- Synchronization of multiple cutting tables – enables cutting and breaking of multiple glass types simultaneously

- Automatic load distribution across several production lines for optimized efficiency

- Rush lite /orders are given higher priority for timely processing

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Project implementation was usually more complicated than we would have thought, but everything always went well in the end (…) I don’t know of any better optimization solutions.

We’ve not missed a beat. June 2020 was the biggest month we’ve ever had in our history. We keep humming along.

Furnace Optimizer

A+W Furnace Optimizer introduces an intelligent solution for toughened safety glass production that aims to maximize furnace bed utilization and energy efficiency simultaneously. By reporting the availability of sheets prior to the glass tempering system, A+W Furnace Optimizer facilitates dynamic and efficient furnace bed occupancy.

This software solution conducts real-time optimization directly in front of the oven, ensuring cost-effective production based on available sheets. Providing a graphical display of furnace bed occupancy and seamless access to booked sheets, A+W Furnace Optimizer offers a user-friendly operation.

Integrated into the production data acquisition system, this software solution furnishes real-time production progress updates, thus enabling precise control of the furnace bedto optimize production processes and maximize machine utilization. With its dynamic, customizable functionality, emphasis on quality assurance, cost efficiency, A+W Furnace Optimizer emerges as the ideal solution for glass industry firms seeking to streamline production processes and bolster competitiveness.

- Graphic display of the furnace bed assignment for efficient monitoring

- Batch-by-batch production and booking of the furnace bed

- Online optimization directly in front of the furnace, based on the available sheets on racks

- Direct access to booked sheets on racks and slot carts via A+W Barcode Manager or A+W Production Terminal

- Ability to save and evaluate batch information in connection with A+W IoT - Smart Trace

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

iQuote

A streamlined solution designed to simplify the process of recalculating quotations and orders. With A+W iQuote, your dealers’ customers can make changes themselves and add notes—such as different delivery addresses or requested delivery dates—depending on the order status.

A+W iQuote integrates seamlessly with your ERP system, ensuring that data is retrieved directly and in real-time from your database. This eliminates delays caused by emails or phone calls, and prevents issues with your dealers’ customers inquiring about non-buildable products. Your dealers and their customers will always see up-to-date products and prices online, which you manage through your ERP system. A+W iQuote adheres to the rules of your A+W ERP system, including the same prices and feasibility and plausibility checks you have established.

- Browser-based product configuration

- Online construction and price calculation

- Data directly calculated and saved in A+W ERP

- Products, prices and discounts from your A+W ERP System

- Integrated authorization based on A+W ERP

- Paperwork done by ERP

- Interface for touch screen

- Order history

- Attractive design

- Responsive Design: made for modern and portable devices (tablets)

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

With A+W iQuote, anything that is ordered can actually be built. The entire order runs through a restriction check based on master data stored in A+W Business. The customer transmits a technically correct complete order to us. There are no questions and time-consuming clarifications by telephone or e-mail. This is how we can achieve much greater efficiency in the entire order process.

iShape

For the production of non-rectangular or extra-large shapes, glass processors frequently receive hand-drawn templates on paper, cardboard, wood, etc. from their customer. In order to fabricate these non-rectangular or larger shapes, modern CNC machines require digital data.

To solve this problem, A+W, in conjunction with Viprotron, developed a user-friendly, easy-to-operate app called A+W iShape.

With A+W iShape you can use your smartphone to photograph the template. The only requirement is A+W’s L-shaped reference objects that have to be placed on the template. Once photographed, the app will digitize the template by transforming the shape into an easy to edit outline, ready to be imported into A+W CAD Designer.

What makes A+W iShape special? In contrast to older solutions, there is no need to calibrate the camera! A+W iShape works with any quality smartphone camera.

- Place the L-shaped reference objects to automatically detect the template/photographed object.

- The L-shaped reference objects help correct any distortions when photographing a template.

- Once photographed, the iShape file can be imported into A+W CAD Designer, where further edits can be done.

- Transfer the DXF file to your CNC machine and start the production.

- Quick, reliable digitalization of templates

- Use of a good smartphone camera instead of an expensive, heavy digital camera

- Automatic import of the photo into the A+W CAD Designer

- Smoothing of the contour via the A+W patented smoothing process

- Output as DXF or A+W CAD format (SN) for use in A+W ERP and control of your machines with quick transfer to CNC machines

- Reliable compensation of distortions thanks to the reference object

- No calibration of the camera required

- Automatic import of the photo into the A+W CAD Designer

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Logistics Optimizer

A+W Logistics Optimizer revolutionizes logistics in the glass industry through automatic route planning and optimization, thus providing an efficient solution for the delivery of glass products.

It automatically creates and optimizes routes and delivery addresses, saving time and money. Based on Nokia Maps, A+W Logistics Optimizer considers truck restrictions and current traffic data to calculate optimal routes, ensuring efficient deliveries.

The mobile app facilitates seamless communication between drivers and the ERP system, which allows for real-time delivery tracking via GPS and almost instant confirmation.

- Automatic creation and/or optimization of routes and delivery addresses & weight (2 modes)

- (Re)calculation based on times, additional stops, and traffic

- Consideration of truck restrictions, tunnels, and traffic

- Printout reports for truck drivers and customs

- Mobile app for drivers and online delivery tracking via GPS

- Feedback to the ERP system possible (e.g., for printing delivery notes and invoices)

- Delivery statistics

- A+W Smart Delivery (delivery app) as a scalable solution, e.g., only for the electronic delivery invoice

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

We’ve not missed a beat. June 2020 was the biggest month we’ve ever had in our history. We keep humming along.

The [A+W] team made a serious and dedicated effort to fix things. And they incorporated new tools like barcode scanning, seeing the product, [and] production scheduling [all of which have] really helped us improve our On-time in Full (OTIF) number.

Production Terminal

A+W Production Terminal transforms production processes within the glass industry by utilizing robust capabilities and an user-friendly interface. This software solution facilitates interactive process visualization, real-time production data acquisition, and seamless control.

One notable feature the A+W Production Terminal is its ability to visualize pane setups, dimensions and processing steps, and provide employees with a clear overview of ongoing processes that require immediate intervention when necessary. Additionally, each terminal supports the display of CAD drawings and document links, which enhance communication and collaboration throughout production.

The integration of A+W Barcode Manager with the A+W Production Terminal is another key aspect, enabling efficient booking of breakage slices and reasons, along with machine status feedback and automatic scrap handling, which collectively enhances productivity, efficiency and processing quality.

- Visualize pane structures, dimensions, and processing steps

- Display of CAD drawings

- Document links for enhanced communication and collaboration

- Booking of breakage and reason

- Booking and feedback of machine status

- Automatic reject handling with implemented downstream concept

- Fully customizable user interface

- Control via foot panel for convenient operation

- Display rack information for subsequent processes

- Online printing of labels

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

My father always used to strive for the optimum production solution. This also applies to the software we are using. We have therefore been using A+W software for more than 30 years, and have never looked back. Another important criterion for us is service. At A+W, this is solution-oriented; their experts know their job and communicate excellently with our staff and machinery partners.

With the A+W Production system, we manage our complex product mix very flexibly. No more sheets are lost. And there are almost no complaints. We produce much greater quantities in the same amount of time. In addition, cutting has generally become more flexible and yield has increased significantly. The realtime optimization and automatic breakage pool also make a contribution here – poor sheets are remade immediately and can frequently still be delivered with the main order.

Rack Optimizer

A+W Rack Optimizer transforms the packaging process in insulating glass production by enabling direct packaging and maximing the utilization of packaging materials. This ensures consistent packaging quality, while reducing reliance on employee expertise.

The software considers unloading sequences and allows for customized sequencing to balance weight and optimize rack loading/unloading, minimizing the needs for order picking and reducing transport costs A 3D visualization provides detailed previews and graphic instructions for packaging optimization.

- Increasing productivity on the IG line, addressing bottlenecks

- Eliminate re-sorting requirements in dispatch

- Potential use of robots for stacking and packaging

- Reduced breakage and rejects through automated glass packaging

- Automatic weight balancing and limit check for packing racks

- 3D pack view for detailed rack loading visualization and item identification

- Manual lite movement using the 3D pack view editor

- Special mode for cases

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Standalone

Solutions without ERP system

Realtime Optimizer

The A+W Realtime Optimizer revolutionizes cutting optimization in glass production by enabling flexible and extensive interventions in manufacturing processes. Even after optimization, runs can be linked, split, and reassembled.

Furthermore, optimization parameters (such as edge cut, etc.) can be changed immediately before cutting. The system distributes optimization runs online to different cutting tables, seamlessly integrates rush orders and damaged glass, while ensuring compliance with the original stacking sequences.

The intelligent utilization of leftover plates maximizes glass yield by automatically or manually identifying and linking residual plates. Additionally, the A+W Realtime Optimizer offers efficient breakage management, marking damaged panes and enabling automatic reproduction.

- Online re-optimization of created jobs from A+W Production or A+W Business Pro (same glass type)

- Consideration of production sequence from the production system

- Possibility of entering rush lites / rush jobs

- Quick-Optimization after cutting was started

- Reduction of residue plates by using rush jobs, breakage, or sheets from following optimizations / jobs

- Dynamic re-optimization of breakage

- Online control of cutting tables and breakout display

- Avoids residue plates by linking and mixing of cutting jobs

- Improves the yield and cutting performance

- Managing local and global breakage with re-optimization

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Standalone

Solutions without ERP system

I love the innovation I see at A+W. Ideas that promote continuous improvement will move the industry ahead.

With A+W Production, we can plan and conduct our production much more efficiently, especially in the interplay with production control and completion reporting by plant data collection. Currently, we are working with A+W on the implementation of a breakage pool, with which we can reproduce defective lites quickly.

Shape Optimizer

The A+W Shape Optimizer is an innovative solution for the glass industry, enabling efficient cutting optimization for custom glass sizes and shapes. With its focus on material savings and productivity, the A+W Shape Optimizer offers features that optimize production processes while reducing material consumption.

An outstanding feature of the A+W Shape Optimizer is its ability to achieve savings of up to 50% in cutting individual glass sizes and shapes. By automatically nesting various model geometries into an encompassing rectangle, it maximizes yield, thus ensuring sustainable “Green Production.”

The A+W Shape Optimizer stands out for its quick setup on any standard cutting line and facilitates a simple breaking process for maximum productivity. Additionally, it considers decoating information in the optimization process and takes the decoating of coated glasses into consideration.

- Savings of up to 50% in cutting individual sheet sizes and shapes

- “Green production” through maximum yield

- Automatic nesting of two different shape geometries into an encompassing rectangle

- Quick setup at any standard cutting line

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

The product is excellent, the service second to none. I can always call the A+W specialists –… experienced engineers who know what they are doing and who never let us down.

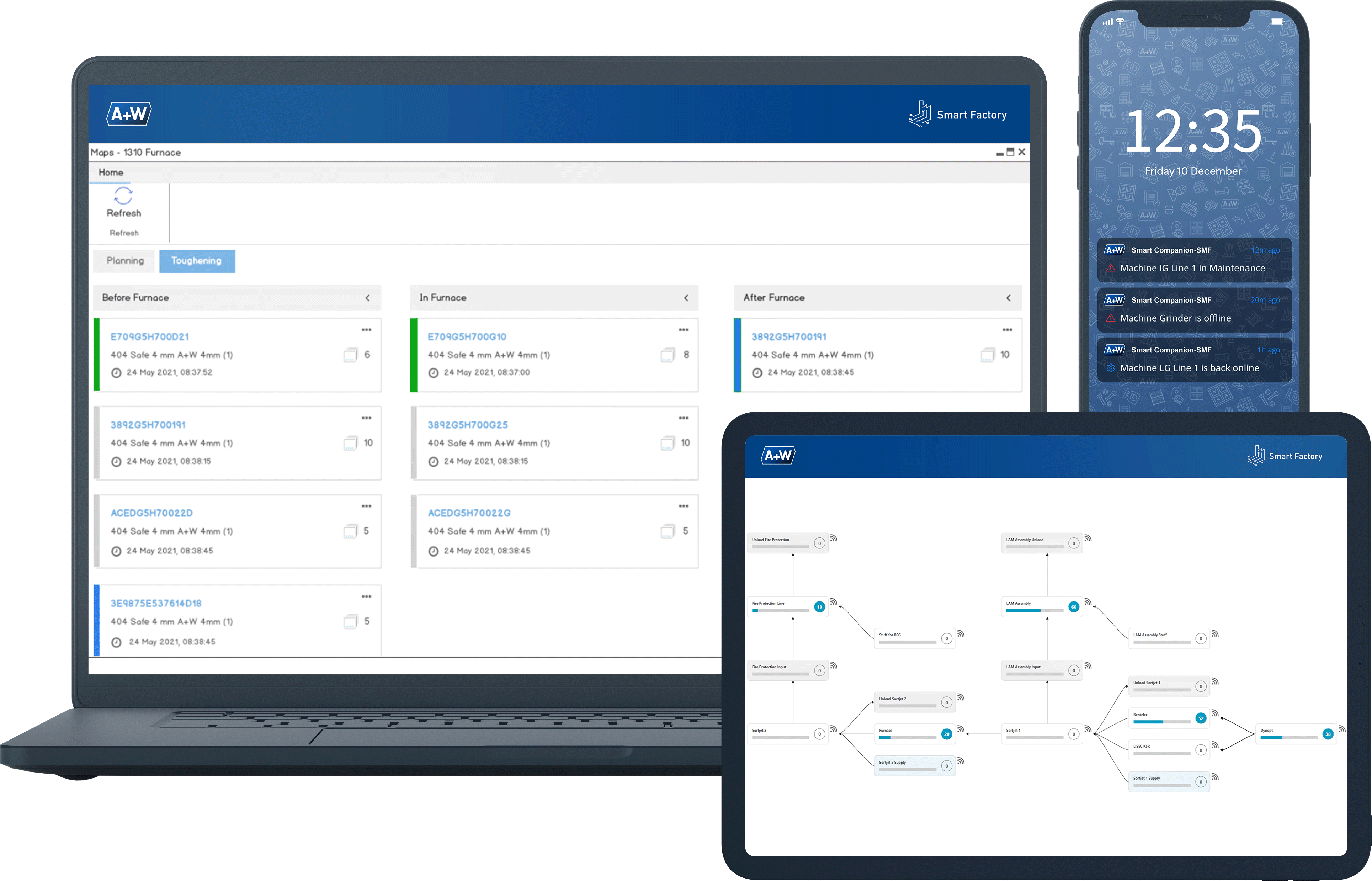

Smart Companion

The A+W Smart Companion revolutionizes warehouse management and logistics in the glass industry through its versatile functions and user-friendly handling. This innovative solution is usable on a mobile device under iOS and Android, offering an intuitive menu navigation that enables easy operation. The A+W Smart Companion can be deployed on various smart devices according to requirements and offers the ability to scan multiple barcodes in continuous mode.

Supporting the entire value chain, the A+W Smart Companion contributes to its digitization, saving time and costs while making processes more flexible. Warehouse management can be digitized with the A+W Smart Companion Stock Module, allowing the use of smart devices as scanner hardware for capturing inputs, outputs, transfers, and changes. During inventory, the Inventory function of the warehouse module supports the process with useful filters, checklists, and dashboards to optimize and simplify the process.

- Runs under iOS and Android

- User-friendly menu guide

- Depending on requirements, can be used on different smart devices

- Scanning of several bar codes in continuous mode

- Continuous digital stock management

- Safe and secure inventory

- Record incoming goods and stock transactions quickly and without errors

- more efficient workflows, no unnecessary running around

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

The [A+W] team made a serious and dedicated effort to fix things. And they incorporated new tools like barcode scanning, seeing the product, [and] production scheduling [all of which have] really helped us improve our On-time in Full (OTIF) number.

I love the innovation I see at A+W. Ideas that promote continuous improvement will move the industry ahead.

Smart Delivery Maps

A+W Smart Delivery Maps is a comprehensive solution for digitizing your delivery processes. The mobile app replaces paper-based workflows with a centralized, intuitive platform that connects drivers, dispatch and accounting.

All relevant order and item data is available directly on the driver’s mobile device. Customers confirm deliveries with an electronic signature, supplemented by photos and comments, which are automatically transferred to your ERP system. This eliminates manual steps, triggers invoicing immediately and improves liquidity.

Real-time documentation ensures maximum transparency: status changes, complaints and special notes are recorded instantly and visible to all stakeholders.

Integrated map material and rack management enable efficient planning and monitoring of deliveries and pickups. Optionally, the solution can be extended with the A+W Logistics Optimizer to intelligently optimize routes and reduce costs.

- Digital delivery and real-time documentation

- Efficient rack management with driver assignment

- Electronic delivery proofs including signature, photos and comments

- Immediate online feedback to accelerate invoicing

- Integrated map material for planning and monitoring

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.