Business Pro

The complete solution for efficient business processes in the flat glass industry

Quickly ready for use

Fully integrated commercial and production technology solution

Versatile

Mapping of all multi-stage production processes

Flexible scheduling modes

Production plannable for speed or margin

Capacity planning

Integrated capacity planning for optimum machine utilization

About the Product

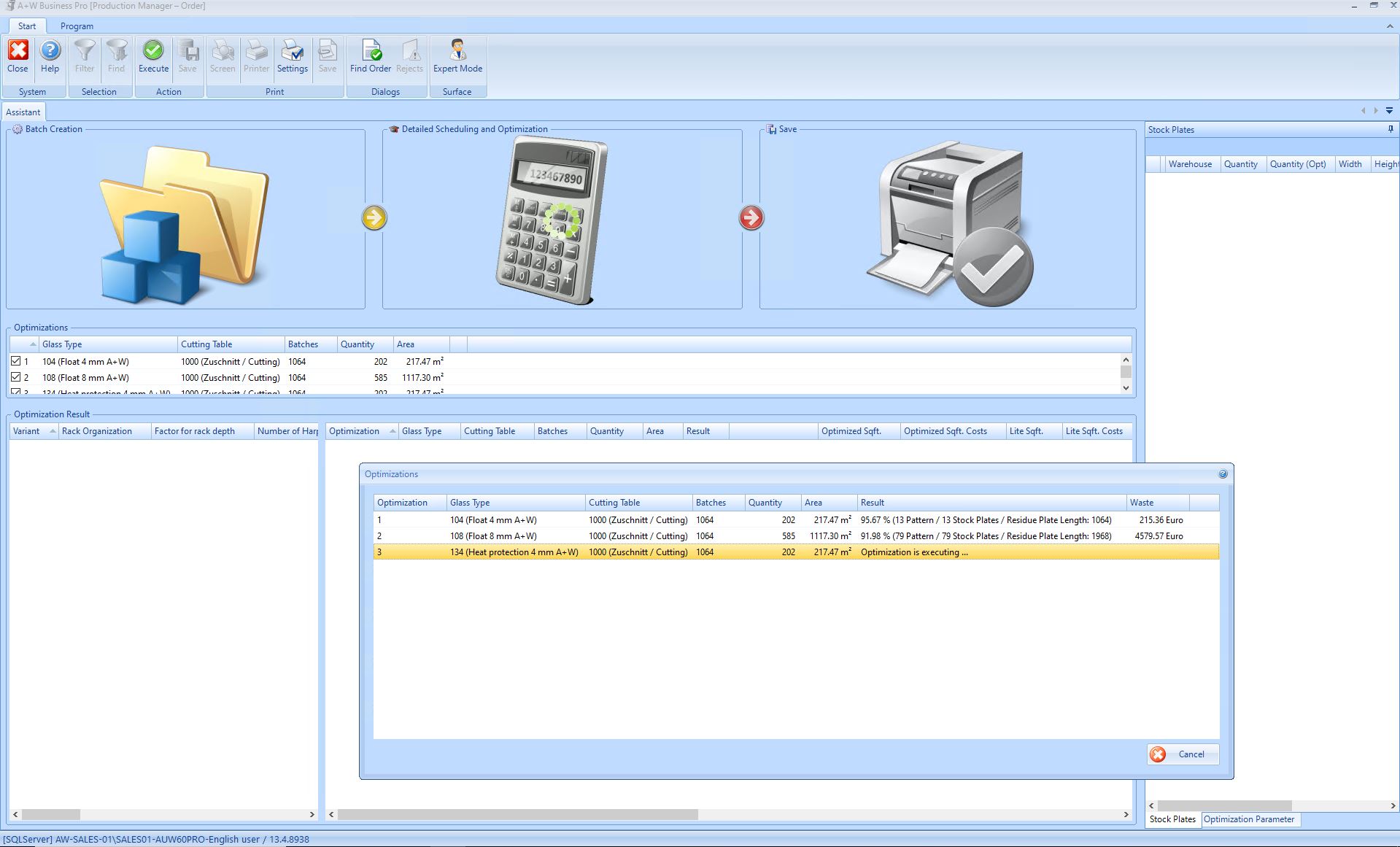

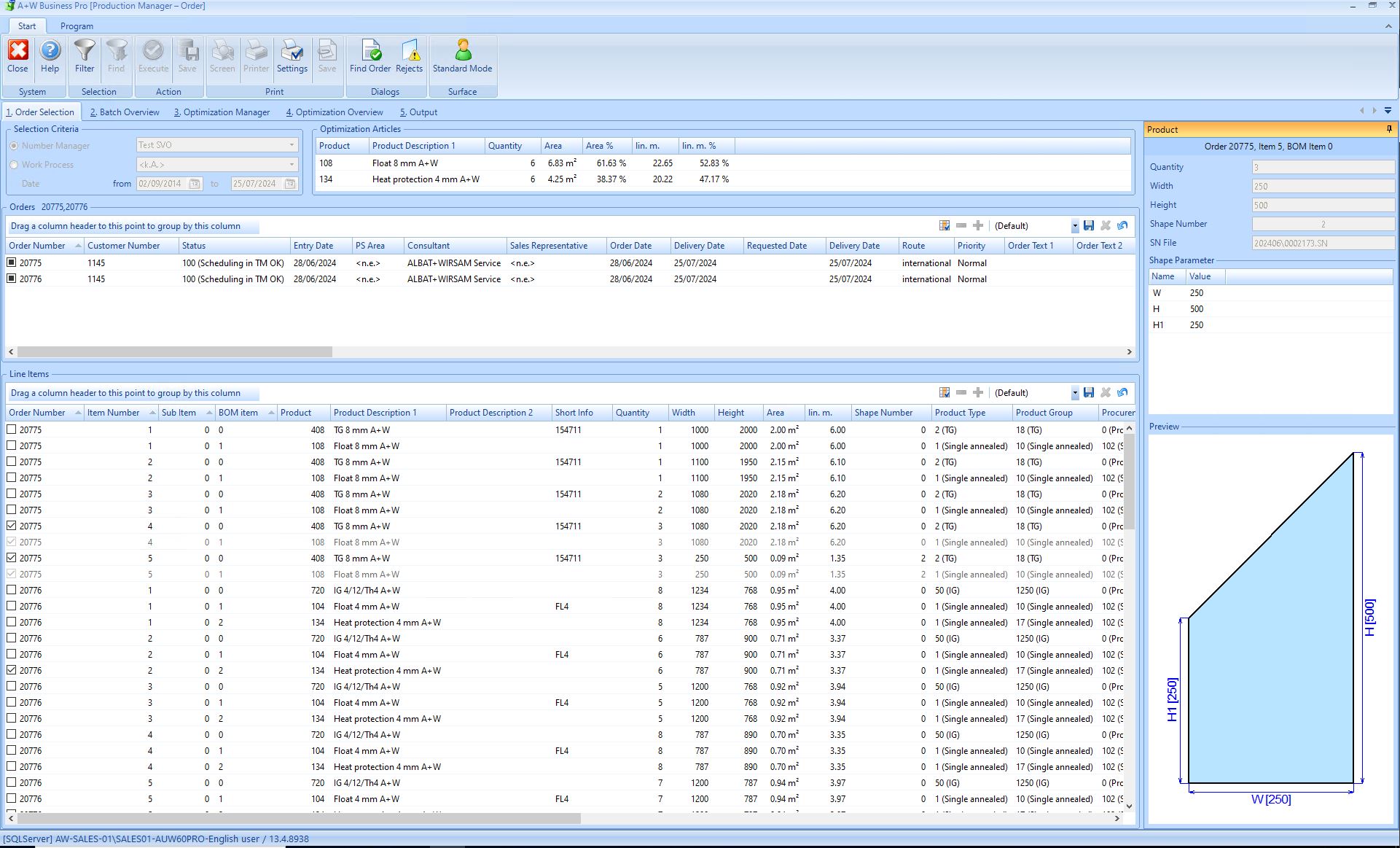

Characterized by swift operational readiness and flexibility, A+W Business Pro enables rapid production release and detailed planning via the wizard function (a.k.a. expert mode). You can also plan your production releases based on speed or profit margin and map the entire multi-stage production process.

Utilize A+W Business Pro to select, reserve, and book stock sheets, optimizing cutting per batch and glass type. Directly control your machines and enable production feedback to ensure accurate stock levels today and in the future.

Functionalities and Benefits

- Fully integrated commercial & production solution

- Expert mode allows for more detailed and optimized planning possible and faster production release

- Quick and easy output of production documents and NC codes for connected machines

- Merging of parts list items into production lots (multi-stage production)

- Selection, reservation, and booking of stock plates

- Cutting optimization per batch and glass type

- Pre-defined production lists and labels

- Direct machine control

- Manage batches for greater optimization

- Correctly layer inventory thanks to feedback from production

Versatile and expandable, this software solution accommodates your company’s growth needs. Benefit from comprehensive master data management and automated processes to streamline operations, all within an affordable software package that increases your business’ success.

Looking to grow? Add modules, such as A+W Rack Optimizer or A+W iShape, to enable greater growth and scalability of your business.

Find out more about A+W Business Pro now by contacting us!

Our Customers

A+W Clarity Reference

Minneapolis Glass

I love the innovation I see at A+W. Ideas that promote continuous improvement will move the industry ahead.

Read more

A+W Clarity Reference

Euroview

The software is the brain and backbone of the company. Our old system was not suitable for the new requirements, so we replaced it with a comprehensive solution from A+W.

Read more

A+W Clarity Reference

Semcoglas Glastechnik

The staff is not supposed to run around the shop floor to gather information but they shall have all the information they need for the production step on hand right at their workstation.

Read more

Most Popular Add-ons

Clarity

CAD Designer

Looking for a CAD system designed specifically for the flat glass industry? Look no further than A+W CAD Designer, which offers innovative design solutions. With intuitive tools, it facilitates the creation of complex free forms and standard templates for reuse in ERP systems.

The special challenge of free-form entry of construction and automobile glass is entering the multitude of parameters quickly and correctly, drawing technically correctly and clearly, and generating reliable CNC code from this.

The A+W CAD Designer enables the entry of lite and contour data, all processings, the takeover of customer CAD data and the digitalization of templates, for example via digitalization table or virtual digitizing.

Moreover, A+W CAD Designer has a bar design program with graphical interface that allows the majority of common bar types to be arranged at will on a rectangular or shaped lite. Bars of different widths can be used in a design, and it is also possible to use different bar types within a bar pattern.

- Simple and quick creation of complex individual shapes and standard template files for re-use in ERP systems

- Easily capture and modify complex shapes and processing steps, such as edge layering or intricate cut-outs

- Correct inaccuracies in digitized shapes using A+W's patented streaming mode

- Easy entering and changing of difficult shapes and processings (for example edge deletion or complex cut-outs)

- Possibility of direct control of your CNC machine

- Easy and quick creation and dimensioning of complex grill pattern designs

- Little training required thanks to graphical tools and modern user guidance

- Direct control of the muntin saw possible

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

The [A+W] team made a serious and dedicated effort to fix things. And they incorporated new tools like barcode scanning, seeing the product, [and] production scheduling [all of which have] really helped us improve our On-time in Full (OTIF) number.

We’ve not missed a beat. June 2020 was the biggest month we’ve ever had in our history. We keep humming along.

Clarity

Logistics Optimizer

A+W Logistics Optimizer revolutionizes logistics in the glass industry through automatic route planning and optimization, thus providing an efficient solution for the delivery of glass products.

It automatically creates and optimizes routes and delivery addresses, saving time and money. Based on Nokia Maps, A+W Logistics Optimizer considers truck restrictions and current traffic data to calculate optimal routes, ensuring efficient deliveries.

The mobile app facilitates seamless communication between drivers and the ERP system, which allows for real-time delivery tracking via GPS and almost instant confirmation.

- Automatic creation and/or optimization of routes and delivery addresses & weight (2 modes)

- (Re)calculation based on times, additional stops, and traffic

- Consideration of truck restrictions, tunnels, and traffic

- Printout reports for truck drivers and customs

- Mobile app for drivers and online delivery tracking via GPS

- Feedback to the ERP system possible (e.g., for printing delivery notes and invoices)

- Delivery statistics

- A+W Smart Delivery (delivery app) as a scalable solution, e.g., only for the electronic delivery invoice

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

I love the innovation I see at A+W. Ideas that promote continuous improvement will move the industry ahead.

The [A+W] team made a serious and dedicated effort to fix things. And they incorporated new tools like barcode scanning, seeing the product, [and] production scheduling [all of which have] really helped us improve our On-time in Full (OTIF) number.

Clarity

Barcode Manager

Barcode scanning and tracking saves your employees and company time and money! A+W offers a wide array of functions to streamline production and process oversight.

Take charge of processing steps, keep track of machine utilization, and also record any breakage with ease using A+W’s barcode solution. This solution lays the groundwork for comprehensive evaluations and future planning, which are vital to your company’s current and future success. From status and storage location bookings (per user, station, machine, rack, item, and sheet) to precise processing entries and machine control via barcode scanning, our solution was designed to specifically meet your needs.

- Status and location bookings per user, station/machine, rack, item & sheet

- Machine start and control of processing via barcode reading

- Automatic reject handling (with implemented downstream concept)

- Statistical evaluations based on barcode readings (e.g. by using Crystal Reports or QLIK)

- Quality improvements based on breakage bookings

- Capacity updates based on barcode readings

- Printout of labels by A+W Production

- Flexible label design thanks to CR

- Centralized display of status information based on barcode readings by extension A+W Production Monitor and/or A+W Production Terminals

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

The A+W software controls and checks all processes from entry of the order to control of the machines, on through to delivery of the finished products. Thanks to consistent barcode control and the A+W Production Monitors, we always know where each sheet is at any point in time. All commercial and technical data is available company-wide – and this without having employees running around all the time with folders and stacks of paper under their arms in order to determine what they must do with which sheet (…) All employees work productively! The focus is always on information, all the time and everywhere.

I love the innovation I see at A+W. Ideas that promote continuous improvement will move the industry ahead.

Clarity

iQuote

A streamlined solution designed to simplify the process of recalculating quotations and orders. With A+W iQuote, your dealers’ customers can make changes themselves and add notes—such as different delivery addresses or requested delivery dates—depending on the order status.

A+W iQuote integrates seamlessly with your ERP system, ensuring that data is retrieved directly and in real-time from your database. This eliminates delays caused by emails or phone calls, and prevents issues with your dealers’ customers inquiring about non-buildable products. Your dealers and their customers will always see up-to-date products and prices online, which you manage through your ERP system. A+W iQuote adheres to the rules of your A+W ERP system, including the same prices and feasibility and plausibility checks you have established.

- Browser-based product configuration

- Online construction and price calculation

- Data directly calculated and saved in A+W ERP

- Products, prices and discounts from your A+W ERP System

- Integrated authorization based on A+W ERP

- Paperwork done by ERP

- Interface for touch screen

- Order history

- Attractive design

- Responsive Design: made for modern and portable devices (tablets)

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

With A+W iQuote, anything that is ordered can actually be built. The entire order runs through a restriction check based on master data stored in A+W Business. The customer transmits a technically correct complete order to us. There are no questions and time-consuming clarifications by telephone or e-mail. This is how we can achieve much greater efficiency in the entire order process.