Home > Products > A+W Clarity Add-ons > A+W Furnace Optimizer

A+W Furnace Optimizer

ALLOTTING FURNACE BEDS OPTIMALLY

The maximum utilization of the furnace bed makes TG production more efficient and cost-effective. In many cases, this cannot be done manually or it is very time-consuming. The results are poorly allocated furnace beds and higher energy and labor costs. A reliable lite tracing is difficult. Employees must always remeasure in order to be sure which lite is actually the one in question and where the pre-tempered lites must be stored at the furnace exit.

With the A+W Furnace Optimizer, the capacities of the TG furnace are used as well as possible and lite tracking is easier. This is an online optimization that works with precisely the lites that are currently available at the furnace entrance. Since these lites were booked in networked production via PDC for the previous processing of the TG production, the furnace manager can identify each lite with a simple barcode reading and position it in the current furnace batch according to the specifications of the A+W Furnace Optimizer.

Functionality and Benefits

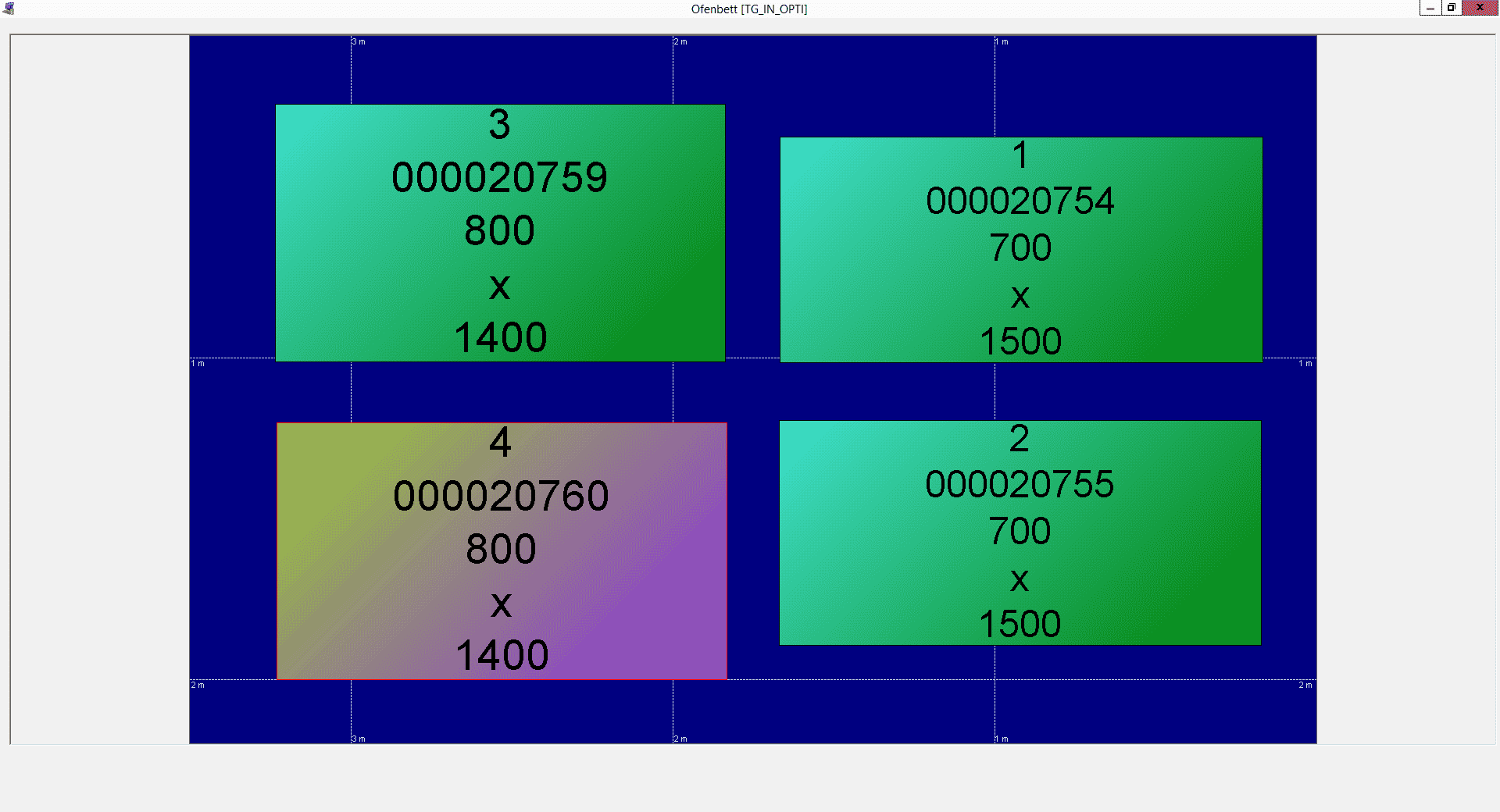

- Graphic display of the furnace bed assignment

- Batch-by-batch production and booking of the furnace bed

- Online optimization directly in front of the furnace, based on the real, available sheets on the racks that are accessible

- Direct access to the sheets on racks and slot carts booked via A+W Barcode Manager or A+W Production Terminal

- In connection with A+W IOT – Smart Trace, the batch information can be backed up and evaluated